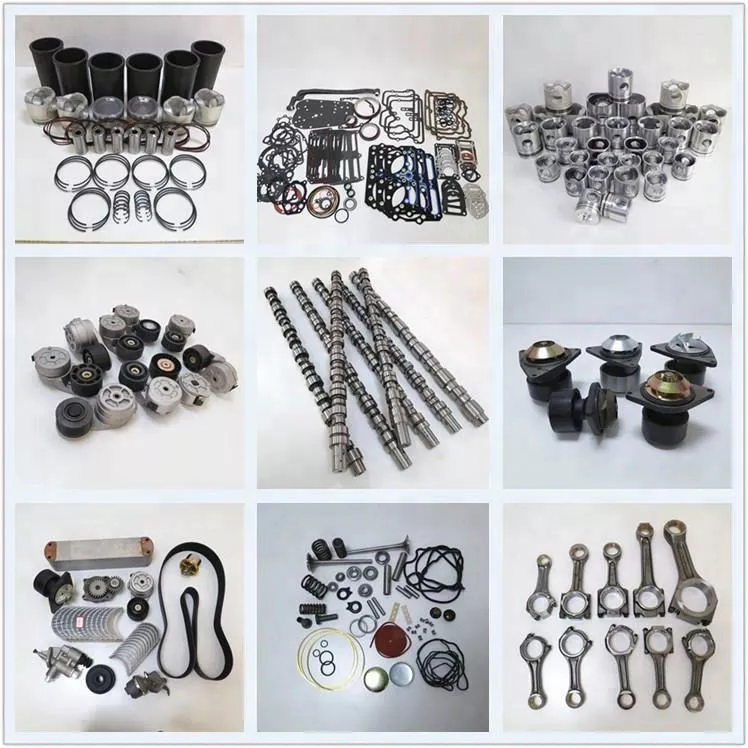

Product Description

construction machine pump

gear pump , hydraulic pump , main pump , WATER pump

fit machine :

Dozer: D31 D53 D60 D65 D75 D80 D85 D135 D155 D355 D375 D475

Loader: WA100 WA120 WA180 WA200 WA320 WA380 WA420 WA450 WA480 WA500 WA600 WA900

EXCAVATOR: PC30 PC35 PC55 PC75 PC120 PC160 PC20 PC220 PC240 PC300 PC350 PC360 PC400 PC450 PC650 PC750 PC1250

MOTOR: GD55 GD605 GD705

DUMP: HD325 HD405 HD460

Engine : 6D95 6D12 6D108 6D110 6D114 6D125 6D140 6D155 6D170

| 705-21-31571 | 114-60-57140 | 113-15-0571 | 6206-51-1201 |

| 705-12-32571 | 705-12-32571 | 705-12-32571 | 6136-51-1002 |

| 704-12-38100 | 07429-71300 | ||

| 704-12-38100 | 07429-72302 | 6150-51-1004 | |

| 704-11-38100 | 07429-71203 | 0571 2-72203 | |

| 704-11-38100 | 07429-71203 | 0571 2-72203 | 6150-51-1004 |

| 0571 3-67503 | 6620-51-1571 | ||

| 0571 1-67503 | 0571 0-72301 | 6150-51-1004 | |

| 0571 1-67503 | 0571 0-72203 | 0571 2-71203 | 6150-51-1004 |

| 705-11-38571 | 14X-49-11600 | 705-51-2571 | 6151-51-1005 |

| 0571 1-67503 | 0571 0-72203 | 0571 2-71203 | 6151-51-1004 |

| 0571 3-67100 | 07428-71202 | 0571 2-72203 | 6659-52-1571 |

| 0571 3-67103 | 07428-71202 | 0571 2-72203 | 6620-51-1571 |

| 0571 4-67504 | 0571 0-71400 | 0571 2-71300 | 6659-52-1571 |

| 705-12-44571 | 0571 0-71400 | 0571 2-71300 | 6151-51-1005 |

| 0571 4-66100 | 0571 2-72103 | 6620-51-1000 | |

| 0571 4-66103 | 0571 6-72202 | 0571 2-71203 | 6710-51-1001 |

| 0571 4-66200 | 0571 6-72202 | 0571 2-71203 | 6710-51-1001 |

| 705-51-30190 | 0571 6-72202 | 705-21-32051 | 6151-51-1004 |

| 571-66103 | 0571 0-72202 | 0571 3-71103 | 6128-52-1012 |

| 571-66200 | 0571 0-72202 | 0571 3-71103 | 6128-52-1012 |

| 07400-10600 | |||

| 705-51-35710 | |||

| 0571 8-66500 | 571-71802 | 0571 8-72902 | 6128-52-1013 |

| 0571 8-66108 | 571-71102 | 0571 8-72202 | 6128-52-1012 |

| 0571 8-66200 | 571-71102 | 0571 8-72202 | 6128-52-1013 |

6735-21-1910 “Plug, Thread”

6735-21-1940 Plug O-Ring

6732-21-1930 O-Ring

6732-29-2110 Liner

6732-21-6280 Seal

6734-21-5111 “Pan, Oil”

6734-21-5570 “Tube , Suction”

6735-21-5720 “Tube, Oil Guage”

6735-21-5690 “Guage, Oil”

6732-21-4160 O-Ring

124-01-55251 Flywheel Assy

6732-31-4180 Gear

6736-31-1100 Crankshaft Assy

6735-21-8100 Main Metal Assy

6732-21-8180 Metal

6736-29-8100 Main Metal Assy

6731-29-8310 Metal

6736-28-8100 Main Metal Assy

6731-28-8310 “Metal, Lower”

6736-27-8100 Main Metal Assy

6736-26-8100 Metal Metal Assy

6736-21-8610 “Thrust Metal Assy, Thrust “

6731-21-8620 “Thrust Metal Assy, Thrust “

6731-26-8410 Metal

6736-39-1220 “Sleeve, Front”

6736-39-1120 “Sleeve, Rear”

6737-32-3100 Connecting Rod A

6732-31-31320 Bushing

6732-31-3410 Piston

6735-31-2140 Kit Engine Piston

6735-31-3571 Piston Ring Assy

6731-31-2150 Kit Engine Piston

6732-41-5440 Insert

6732-41-3111 Rod Push

6735-41-1111 Camshaft

6732-41-1280 Key

6732-41-1220 Support

6732-41-2110 Tappet

6731-51-1111 Oil Pump Assy

6732-61-6140 Bolt

6731-61-2151 Valve

6735-61-2190 Spring

6736-61-5170 Head Assy

6735-61-2260 Head

6736-61-5180 Adapter

6735-61-2110 Core

6732-51-4431 Gasket

6735-61-2160 Plunger

6735-51-5141 Cartridge

6735-71-1120 Injection Pump A

6735-71-5310 “Tube , Injection Nos,1”

6735-71-5320 Tube Injection Nos. 2

6735-71-5330 Tube Injection Nos. 3

6735-71-5340 Tube Injection Nos 4

6735-71-5350 Tube Injection Nos. 5

6735-71-5360 Tube Injection Nos. 6

6735-71-5550 Connector

6734-71-5310 “Tube, Spill”

6735-71-5260 Hose

6731-81-9190 Spacer

6736-71-5781 Lift Pump

124-01-55160 “Head, Filter”

6732-71-6650 Adapter

124-01-55180 Hose

124-01-55290 Tube

6732-71-6111 “Cartridge, Fuel Filter”

6742-01-5157 “Washer, Sealing “

6735-71-3821 Cartidge Fuel Filter

6735-11-3130 “Kit, Injector”

6732-71-6230 “Seal, Banjo Connector”

6732-11-3850 “Seal, Rectangular Ring”

6736-11-3430 Seal Injector

6731-81-9210 SoleNosid

6736-61-1202 Water Pump Assy

6735-61-1102 “Pump, Water”

6732-61-3320 “Support, Fan “

6732-61-3450 Ring

6732-61-3420 Bearing

6732-61-3410 Hub

6732-61-3430 Retainer

6732-61-3130 Pulley

6732-91-1550 “Pulley, Accessory”

6731-61-4141 Tensioner

6732-81-3330 Belt

6735-81-6110 Alternator A (40A)

124-01-55380 Fan

124-01-55430 Pulley

6735-81-6600 Support

6735-81-6190 Brace

124-01-55440 Retainer

6735-81-6180 Gasket

600-615-2170 Switcheater

124-01-51941 Wire

08038-571 Cap

124-01-61100 Air Cleaner Assy

124-01-61110 Body

600-181-6740 Element Assy

600-181-6820 Element Assy (outer)

08670-57101 Indicator (Dust)

124-01-51191 Nipple

6131-11-4520 Band Assy

6643-11-4630 “Pin, With Thread”

124-01-51151 Bracket

195-979-5190 Collar

600-181-2630 PRE-Cleaner Assy

6672-82-7550 Cover Assy

6672-82-7510 Sleeve Assy

6110-83-7590 Trap

600-181-3850 Cap

124-01-61660 Collar

124-01-51330 Muffler

124-01-5122 Pipe

124-01-51360 Exhaust Pipe

7861-93-3320 “Sensor, Water Temerature”

124-01-51640 Pipe

6130-12-8610 Cap

0571 9-00070 Clamp

6301-11-4630 Plate

6110-23-6490 Spacer

124-01-51412 Bracket

08073-10505 “Switch Oil, Pressure”

124-06-64321 Switch

124-01-61920 Wire Assy

08034-571 Band

600-863-5111 Starting Motor Assy

124-01-51744 “Cover , Alternator”

124-01-51450 Cushion

07095-25713 Cushion

124-06-64482 Wiring Haness

22U-06-11270 “Fussible Link, 65A”

124-12-51141 Damper Disc Assy

124-12-51132 Shaft

04065-5710 Ring

06000-06207 Bearing

12F-14-11290 Yoke

124-03-63340 Radiator Core Assy

114-03-48160 Cap

5710-50004 Valve

124-03-61132 Guard

124-03-51212 Hose (Upper)

124-03-51221 Hoser (Lower)

113-03-21160 Seat

135-03-12110 Damper

114-03-51510 Tank

How to Fix a Faulty Drive Belt Tensioner

If you’re experiencing grinding, squeaking, or other unusual sounds from your car, your drive belt tensioner may be the culprit. In this article, we’ll discuss why a failed drive belt tensioner may need to be replaced and how to fix it. Once you have determined that your belt tensioner is faulty, you can use a Wrench to remove it and replace it with a new one. After you replace the belt tensioner, it will no longer be making noises.

Problems with timing belt tensioner

Whenever your engine is making strange noises, it is likely that the timing belt tensioner is causing the problem. A bad timing belt tensioner is a big cause of such sounds, as the timing of the engine is critical. When the belt is moving properly, the camshaft and crankshaft are perfectly synchronized, and the valves work in perfect sync during the intake and exhaust strokes of each cylinder.

Other signs of a worn tensioner include rust bleeding and dripping. Usually, rust will appear at the mounting bolts and “stops” on the tensioner. Other symptoms of a worn timing belt tensioner are noise, resistance, and roughness. If any of these symptoms are present, it’s important to get the car fixed as soon as possible. Troubleshooting problems with timing belt tensioner is an easy process if you know the symptoms.

If your car starts making squeaking or grinding noises when you drive, it’s probably the timing belt tensioner. The timing belt can also cause problems with your engine’s valves. When the timing belt is too loose, the valves cannot fully combust the fuel-air mixture. If this problem is left undiagnosed, it could result in severe engine damage. To solve the problem, you must replace the timing belt tensioner.

The repair of the timing belt tensioner is not a difficult job if you’re experienced and comfortable with DIY car repairs. If you have a good knowledge of car repair, you can try to replace it yourself – but don’t forget that it is a complex repair job that requires a lot of skill. So, it’s best to hire a professional mechanic. And if you don’t have the necessary tools and training, you can always try the DIY method.

Other symptoms of a bad timing belt tensioner include an abnormal chirping noise, misfiring, and check engine light malfunction. If you notice any of these symptoms, you should replace the timing belt tensioner as soon as possible. Often, the belt is wearing out and can’t spin freely. You may have to replace the timing belt tensioner to avoid major damage to your engine. The best way to tell if the timing belt tensioner is failing is to check it regularly.

Cost of a new drive belt tensioner

A new drive belt can be expensive. Replacing 1 is usually a straightforward task that requires little knowledge, but some cars are more difficult than others. Replacing a drive belt by yourself may result in the replacement of parts you do not know. You may also encounter problems that cannot be resolved unless you have a mechanic check all the affected parts. You can save money by taking the car to a mechanic before trying to fix the problem yourself.

A drive belt tensioner should last at least 125,000 miles, but can break sooner. Most car mechanics will replace the tensioner after you notice the belt is slipping. It takes about 15 minutes to an hour to replace 1 of these parts, and you can do it yourself with the proper tools. You can also ask about the replacement of pulleys or sprockets. The price of a new drive belt tensioner depends on the make and model of your car.

The average cost to replace a drive belt tensioner is between $235 and $267. This cost includes labor and parts, but doesn’t include taxes or fees. Some vehicles may need related repairs as well, such as serpentine belts or tensioner housing. For a detailed estimate, use the RepairPal Fair Price Estimator. You can compare labor costs and shop for the best price. There are many options available online, and you can choose the most convenient 1 for your needs.

In addition to replacing the drive belt, you should also check the idler pulleys, which do not drive anything. If they have excessive movement, replace them. A failed drive belt tensioner can cause the belt to slip and affect other components of the car. You may also notice warning lights that indicate a problem with the alternator, water pump, or power steering. You should also check your vehicle’s air conditioning.

Replacing the tensioner pulley can be done yourself for about $50. Depending on the type of pulley and belt, you may need to replace other parts of the engine as well. You can save money by replacing a tensioner pulley yourself if you have the time and skills. It’s easy to replace a new drive belt tensioner if you’re a mechanically inclined individual.

Repair options for a failed drive belt tensioner

A failed drive belt tensioner may have several symptoms. For instance, it can make a grinding or squealing sound, and it may emit a burning smell. The battery light on your car may also stay on. These are all signs that your drive belt has failed. However, these symptoms are not always indicative of the failure of the drive belt tensioner. Listed below are some common problems that can be caused by a failed drive belt tensioner.

To check for a failed drive belt tensioner, turn off the engine and examine the arm. If it doesn’t move, it’s time to replace the drive belt. A manual drive belt tensioner is easy to replace. A hydraulic or bad spring drive belt tensioner, however, will not be able to be fixed. If you can’t find a repair shop in your area, visit 1 of NAPA AutoCare locations, or a NAPA online store. They will be able to diagnose the failure and provide solutions for your car.

A spring tensioner is a type of drive belt tensioner that uses a spring-loaded pulley to apply the proper tension to the drive belt. However, spring tensioners can fail and seize if not properly maintained. A hydraulic tensioner uses hydraulic oil under pressure and can malfunction. In some cases, the tensioner can leak oil or lose its ability to tension the drive belt. It can also be damaged by excessive wear, which will cause the belt to break.

A failed drive belt tensioner can affect your car’s performance and functionality. In addition to making your car squeaky and jerky, a failed drive belt tensioner can cause the serpentine or v-belt to slip and wear out prematurely. Repairing a failed drive belt tensioner can also prevent your car from experiencing the same problems in the future. So, what do you do if you find your drive belt is slipping?

If your drive belt tensioner isn’t the problem, you’ll have to replace it. In some cases, a loose tensioner arm can lead to cracks in the tensioner housing. In the worst case scenario, the damaged tensioner can also lead to an overheated engine. Ultimately, a failed drive belt tensioner can cause your car to experience overheating, weak battery charging, and even a weakened power steering system.

Maintenance requirements for a drive belt tensioner

Drive belt tensioner maintenance begins with proper alignment of the pulleys. Misaligned pulleys or drives can wear a belt out too fast. Misalignment can occur if the component was recently replaced. A set of shims can restore the pulleys to the proper alignment. It is important to regularly check the tensioner to ensure proper function. Also, check the belt for cracks or wear.

Before performing any maintenance work, always turn off the drive to protect the motor. The belt should be in a safe position so that it will not fall on the workers. Lock down any moving parts and ensure the fans do not freewheel. When inspecting the drive belt tensioner, examine the belt guard for wear and debris. If the belt is damaged or has excessive heat, it is necessary to clean it or replace it.

It is important to maintain a proper fit between the belt and the drive belt tensioner. An incorrectly-sized drive belt will be difficult to install and adjust. An incorrect-rib count drive belt will fit, but will not last as long. Likewise, drive belts with too many ribs will not last as long. For these reasons, drive belt tensioners should be replaced when they are over 50,000 miles.

A drive belt tensioner is a pulley that rides on the outside surface of the serpentine belt. Its purpose is to maintain constant pressure on the pulleys that power car components. It is typically mounted on the front of the engine, bolted to the crankshaft, and rests against the serpentine belt. If the drive belt is cracked, it needs to be replaced immediately. If the arm is loose or bent, the bearings in the tensioner are probably worn.

The drive belt tensioner is an important part of the drive system, which is essential for smooth operation of the vehicle. However, it does wear out prematurely and should be replaced at a certain mileage. It should also be inspected for normal wear and tear as a result of road dirt, excessive heat, and oil leaks. However, it is important to remember that drive belts are highly sensitive to excessive heat, road dirt, and oil leaks.