Product Description

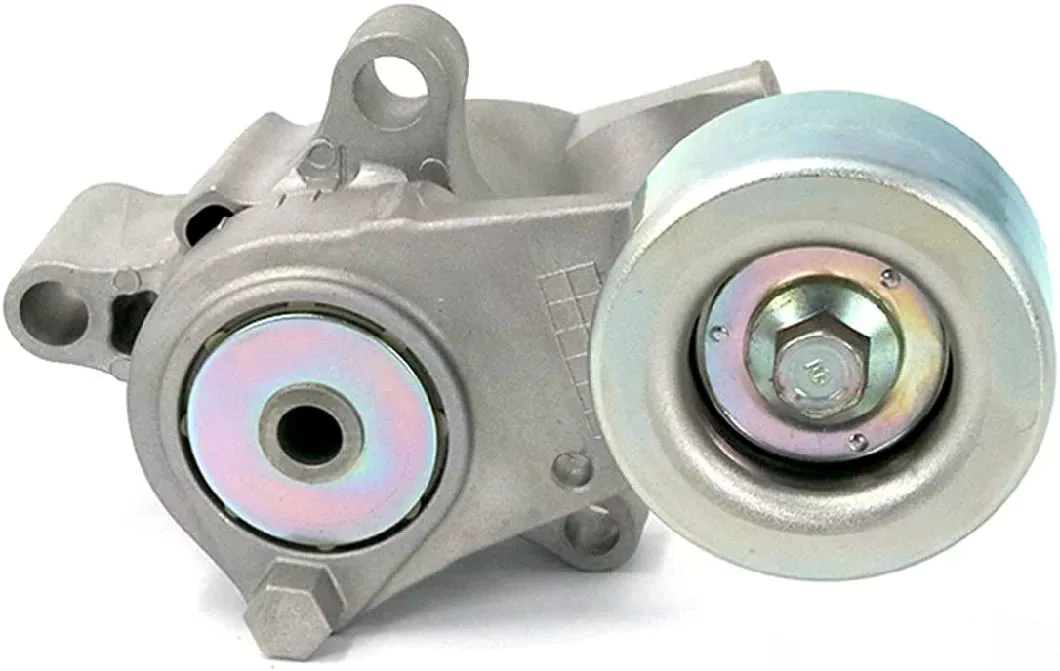

Replacement Original CZPT 923944.1229 Belt Tensioner for Container Equipment Reach Stacker Spare Parts,

With good price and original.

Item Specifics

Part Name: Belt Tensioner

Part No: 923944.1229

Compatable with: CZPT

Market Type: Original

| Detailed Photos |

Kalmar Container Handler Spare Parts 923944.1229 Belt Tensioner

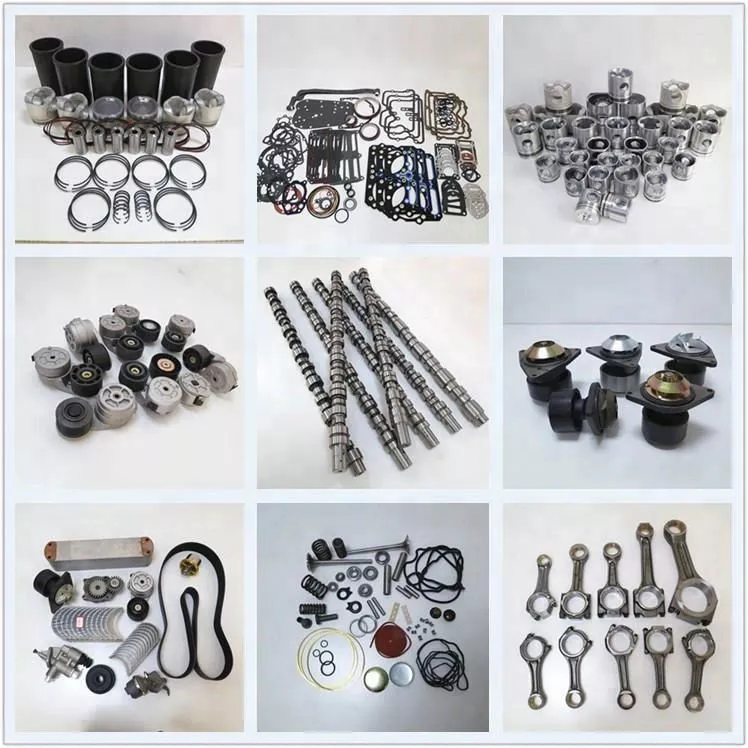

| Container Reach Stacker Parts |

Power System

Engine Transmission Assembly, Turbine Shaft, Hub Assembly, Transmission Plate Assembly, Pump Transmission Assembly, Front Wheel Drive, Transmission Gear Set, Clutch Shaft Assembly, Electric Control Valve Assembly, Handling Cover Assembly, Pressure Regulating Valve, Chongye Pump, Control Valve box cover assembly, electronic control valve assembly, double filter, fuel assembly, cooling assembly, intake assembly, air filter, intake pipe bracket, exhaust assembly, muffler

Frame Assembly

Fixed weight system, fender, cover, rearview mirror assembly, wind deflector assembly, cover assembly

Front window wiper assembly, rear window wiper assembly

double pedal

Air Conditioning System

Boom Assembly

Pitching cylinder, lower slider assembly, upper slider assembly, damping cylinder, telescopic cylinder assembly

Spreader Body

Right telescopic beam assembly, twist lock mechanism, ejector rod device, twist lock device, push rod assembly, slider seat assembly, lubricating oil pipeline assembly, reducer, main beam assembly, telescopic cylinder, hydraulic system, one-way Valve, Rotary Valve, Solenoid Reversing Valve, Telescopic Lock Valve Group

| Company Profile |

HangZhou CZPT Technology Equipment Co., Ltd is a high-tech enterprise that integrates scientific research, design, production and sales. The company has strong technical force, advanced production technology, complete facilities, and has several senior technical engineers, constantly introducing more high-tech products suitable for market needs, which have good functional effect, and great market competitiveness.

In the process of development, the company continuously exchanges and cooperates with many domestic scientific research institutions. The ability to design, produce, maintain, debug and transform projects has rapidly increased, and the scale has continued to expand.

The company’s aim is to provide customers with quality and cheap products, and provide considerate service. In order to meet different needs, we supply high-quality products for the industrial-grade market and provides regular-quality products for professional-level markets and users. As a professional manufacturer, we independently researches and develops a variety of professional production equipments that are suitable for the characteristics of its products. At the same time, we can also customize them according to your requirements.

| Packing and Shipping |

We supply CZPT / Konecranes / CZPT / Fantuzzi / CVS port machinery empty container reach stacker spare parts.

If you need these,please contact us. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Belt Tensioner |

|---|---|

| Application: | Hoisting Machinery |

| Part Name: | Belt Tensioner |

| Part Number: | 923944.1229 |

| Part Name 2: | Cable Drag Chain |

| Part Name 3: | Accumulator Pressure Brake Valve |

| Customization: |

Available

| Customized Request |

|---|

Can you provide guidance on the selection and sizing of belt tensioners for specific belt applications?

When selecting and sizing belt tensioners for specific belt applications, several factors need to be considered to ensure optimal performance and longevity. Here’s a detailed guidance on the selection and sizing of belt tensioners:

- Belt Type and Size:

- System Requirements:

- Tensioner Type:

- Tensioner Design and Mounting:

- Tensioner Load Capacity:

- Environmental Considerations:

- Manufacturer Recommendations:

Start by identifying the type and size of the belt used in the application. Belts can vary in terms of width, length, profile (V-belt, timing belt, etc.), and construction material (rubber, polyurethane, etc.). The tensioner should be compatible with the specific belt type and size to ensure proper fit and functionality.

Consider the requirements of the belt-driven system. Evaluate factors such as the desired tension level, operating speed, load conditions, and environmental factors. The tensioner should be capable of providing the required tension force while accommodating the system’s operating parameters.

Choose the appropriate tensioner type based on the application’s needs. Common types include automatic tensioners, idler pulley tensioners, spring-loaded tensioners, and hydraulic tensioners. Each type has its advantages and limitations, so select the one that best suits the specific belt application.

Consider the design and mounting requirements of the tensioner. Evaluate the space availability, mounting configuration, and alignment with other components in the belt drive system. Some tensioners offer adjustable mounting positions or different design variations to accommodate various installation scenarios.

Check the load capacity of the tensioner to ensure it can handle the expected loads and forces in the belt system. Consider factors such as the belt tension, shock loads, and dynamic forces. The tensioner should have adequate load capacity to prevent premature wear or failure under normal operating conditions.

Assess the environmental conditions in which the tensioner will operate. Factors such as temperature extremes, moisture, dust, chemicals, and exposure to UV radiation can impact the tensioner’s performance and durability. Choose a tensioner that is designed to withstand the specific environmental challenges of the application.

Refer to the manufacturer’s guidelines and recommendations for selecting and sizing the tensioner. Manufacturers often provide technical data, specifications, and selection guides that assist in choosing the appropriate tensioner for specific belt applications. Follow their recommendations to ensure compatibility and optimal performance.

It is important to note that the selection and sizing of belt tensioners may require technical expertise and consideration of specific application requirements. If in doubt, consult with belt tensioner manufacturers or industry experts who can provide further guidance based on their knowledge and experience.

In summary, when selecting and sizing belt tensioners for specific belt applications, consider the belt type and size, system requirements, tensioner type, design and mounting, load capacity, environmental conditions, and manufacturer recommendations. By carefully evaluating these factors, you can choose a suitable tensioner that ensures proper tensioning, reliable operation, and extended belt life in the belt-driven system.

Can belt tensioners be customized or modified for unique industrial or automotive needs?

Belt tensioners can indeed be customized or modified to meet unique industrial or automotive needs. The design and functionality of belt tensioners can be adapted to specific requirements, allowing for greater versatility and compatibility in various applications. Here’s a detailed explanation of how belt tensioners can be customized or modified for unique needs:

- Tensioner Design:

- Tensioner Material:

- Tensioner Force and Range:

- Tensioner Damping and Vibration Control:

- Environmental Considerations:

- Integration with Monitoring Systems:

The design of belt tensioners can be customized to accommodate different space constraints, mounting configurations, and belt drive layouts. Manufacturers can offer various tensioner designs, including compact tensioners, offset tensioners, or multi-belt tensioners, to address specific installation requirements. By adapting the tensioner design, it becomes possible to integrate the tensioner seamlessly into unique industrial or automotive systems.

Belt tensioners are typically constructed using durable materials such as cast iron, steel, or aluminum. However, for specific applications that involve extreme temperatures, corrosive environments, or weight considerations, the tensioner material can be customized. For example, in high-temperature environments, tensioners can be made from heat-resistant alloys or ceramics. Customizing the tensioner material ensures optimal performance and longevity in unique operating conditions.

The tensioning force and tension range of belt tensioners can be tailored to suit specific applications. Different industrial or automotive systems may require varying tension levels based on factors like load requirements, operating conditions, or desired power transmission efficiency. Manufacturers can customize the tensioner force and range to match these specific needs, ensuring the proper tension is maintained in the belt drive system.

Customized belt tensioners can incorporate damping and vibration control features to address specific noise and vibration requirements. In applications where noise reduction or vibration dampening is critical, tensioners can be modified with additional components or materials to absorb or dampen vibrations, resulting in smoother and quieter operation.

Specialized belt tensioners can be customized for unique environmental conditions. For instance, in applications exposed to high levels of dust, moisture, or chemicals, tensioners can be modified with protective coatings, seals, or materials that enhance resistance to corrosion, abrasion, or contamination. By customizing the tensioners to withstand harsh environments, their performance and service life can be optimized.

In some cases, belt tensioners can be modified to integrate with monitoring systems or sensors. This customization allows for real-time monitoring of belt tension and condition, enabling proactive maintenance or automated adjustments. Integration with monitoring systems provides enhanced control and efficiency, particularly in critical industrial or automotive applications.

In summary, belt tensioners can be customized or modified to meet unique industrial or automotive needs. Customization options include adapting the tensioner design, selecting appropriate materials, adjusting the tensioning force and range, incorporating damping and vibration control features, considering environmental factors, and integrating with monitoring systems. By customizing belt tensioners, they can be optimized for specific applications, ensuring reliable performance and longevity in diverse operating conditions.

What industries and machinery commonly use belt tensioners for optimal belt performance?

Various industries and machinery rely on belt tensioners to achieve optimal belt performance. Here’s a detailed explanation of the industries and machinery that commonly use belt tensioners:

- Automotive Industry:

- Industrial Machinery:

- Power Generation:

- Agricultural Equipment:

- Construction and Mining:

- HVAC and Refrigeration:

The automotive industry extensively utilizes belt tensioners in vehicles for various applications. Belt tensioners are commonly found in the engine accessory drive system, where they maintain the proper tension in the serpentine or V-belts that power components such as the alternator, air conditioning compressor, power steering pump, and water pump. Belt tensioners ensure efficient power transmission, reduce belt slippage, and contribute to the overall reliability and performance of automotive engines.

A wide range of industrial machinery relies on belt tensioners for optimal belt performance. Industries such as manufacturing, food processing, packaging, printing, and material handling use belt-driven systems for conveyor belts, production lines, pumps, compressors, and other equipment. Belt tensioners help maintain the proper tension in these applications, ensuring smooth operation, efficient power transmission, and minimizing downtime due to belt slippage or failure.

In the power generation sector, belt tensioners are commonly used in applications such as generators, turbines, and auxiliary equipment. These systems often utilize belts to transfer power between components, and the tensioners play a crucial role in maintaining proper belt tension. Belt tensioners help optimize power transmission efficiency, reduce vibrations, and enhance the overall reliability of the power generation equipment.

Agricultural machinery, including tractors, combines, and other farming equipment, often rely on belt-driven systems for various operations. Belt tensioners are utilized to maintain the tension in belts powering agricultural implements, such as harvesters, balers, and grain conveyors. By ensuring optimal tension, belt tensioners contribute to the efficient operation of agricultural equipment, improving productivity and reducing maintenance requirements.

Construction and mining industries commonly employ belt-driven systems in equipment such as excavators, loaders, crushers, and conveyor systems. Belt tensioners are used to maintain the proper tension in belts powering these machines, ensuring reliable and efficient operation in demanding environments. Belt tensioners help prevent belt slippage, reduce downtime, and contribute to the longevity of the equipment.

The HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industries rely on belt-driven systems for various applications, including fans, blowers, compressors, and pumps. Belt tensioners are critical in maintaining the proper tension in these systems, ensuring efficient power transmission and reducing belt-related issues such as slippage or premature wear. Belt tensioners contribute to the overall performance and reliability of HVAC and refrigeration equipment.

In addition to the industries mentioned above, belt tensioners are also utilized in a wide range of other machinery and equipment, including woodworking machinery, textile machinery, marine propulsion systems, and more. The versatility and benefits of belt tensioners make them a valuable component for achieving optimal belt performance in numerous industrial and mechanical applications.

editor by CX 2024-05-03

China supplier Agricultural Auto Trailer Front Wheel Hub Unit Car Motorcycle Spare Parts 6004 6203 6205 6310/C3 Price OEM Deep Groove Ball Bearing near me manufacturer

Product Description

QUICK OVERVIEW

| Model | Agricultural Auto Trailer Front Wheel Hub Unit Car Motorcycle Spare Parts /C3 Price OEM Deep Groove Ball Bearing |

| Greese/Oil | As your requirement, such as open, z,zz,rz, 2rz,rs, 2rs, and so on. |

| Vibration | Z1/V1,Z2/V2,Z3/V3 |

| Tolerance codes | ABEC-1, ABEC-3, ABEC-5, ABEC-7 |

| Internal clearance codes | C0, C2, C3, C4, C5 |

| Snap ring | N, NR |

| Quality level | Reach the same level as Japanese and European bearings, P0 P2 P4 P5 P6.. |

| Feature | Low voice, High speed, Low friction, long service life |

| Application | Pharmaceutical equipment, medical equipment, textile machinery and accessories, knitting machines, weaving machines, spinning equipment, textile accessories, non-woven fabric machinery, textile equipment, machinery, metal, mold, automotive electronics, electrical, instrumentation, military, aviation aerospace, plastics and rubber industry, medical and other fields. |

| Package | 1,barreled package+outer carton+pallets 2,single box+outer carton+pallets 3,tube package+middle box+outer carton+pallets 4,According to your’s requirement |

| Details | We have a complete process for production and quality assurance to make sure our products can meet your requirement. 1.Assembly 2.Windage test 3.Cleaning 4.Rotary test 5.Greasing and gland 6.Noise inspection 7.Appearance inspection 8.Rust prevention |

Deep groove ball bearings are the most representative structure in rolling bearings and have been widely used in many industries, such as cars, compressors, construction, electric motors, food industry, home appliances, etc. They are suitable for high or even extremely high-speed operation, and very durable, and need not be maintained regularly. This kind of bearing has a small friction coefficient, high limit speed. Widely used in industrial machinery, automobile, electrical system.

Application and popular suitable models:

1.Motorcycle rear wheel bearing: 63032RS, 6302 2RS

2.High-speed ball bearing for electric tools: 628ZZ, 688ZZ

3.Bearing for electric motor: 6204 2RS, 6205 2RS

4.Skateboard rubber roller bearings: 608 2RS, 6072RS, 6092RS, 6282RS

5.Stainless steel deep groove ball bearings for the food industry: S6900 2RS, S6901 2RS

6.Ceiling fan bearing: 6202 ZZ, 6203 ZZ

7.Thin wall deep groove ball for sweeper: 6900, 6800 series

Pictures

Model List (Please contact with us for more models)

| Product | Bore Dia (d) (mm) | Outer Dia (D) (mm) | Width (B) (mm) | Radius (min) (rs) (mm) | Dynamic Load Rating (Cr) (N) | Static Load Rating (Cor) (N) |

| 6000 | 10 | 26 | 8 | 0.3 | 4,550 | 1,950 |

| 6000-2RS | 10 | 26 | 8 | 0.3 | 4,550 | 1,950 |

| 6000ZZ | 10 | 26 | 8 | 0.3 | 4,550 | 1,950 |

| 6200 | 10 | 30 | 9 | 0.6 | 5,100 | 2,400 |

| 6200-2RS | 10 | 30 | 9 | 0.6 | 5,100 | 2,400 |

| 6200ZZ | 10 | 30 | 9 | 0.6 | 5,100 | 2,400 |

| 6300 | 10 | 35 | 11 | 0.6 | 8,100 | 3,450 |

| 6300-2RS | 10 | 35 | 11 | 0.6 | 8,100 | 3,450 |

| 6300ZZ | 10 | 35 | 11 | 0.6 | 8,100 | 3,450 |

| 6001 | 12 | 28 | 8 | 0.3 | 5,100 | 2,400 |

| 6001-2RS | 12 | 28 | 8 | 0.3 | 5,100 | 2,400 |

| 6001ZZ | 12 | 28 | 8 | 0.3 | 5,100 | 2,400 |

| 6201 | 12 | 32 | 10 | 0.6 | 6,800 | 3,050 |

| 6201-2RS | 12 | 32 | 10 | 0.6 | 6,800 | 3,050 |

| 6201ZZ | 12 | 32 | 10 | 0.6 | 6,800 | 3,050 |

| 6301 | 12 | 37 | 12 | 1 | 9,700 | 4,200 |

| 6301-2RS | 12 | 37 | 12 | 1 | 9,700 | 4,200 |

| 6301ZZ | 12 | 37 | 12 | 1 | 9,700 | 4,200 |

| 6002 | 15 | 32 | 9 | 0.3 | 5,600 | 2,850 |

| 6002-2RS | 15 | 32 | 9 | 0.3 | 5,600 | 2,850 |

| 6002ZZ | 15 | 32 | 9 | 0.3 | 8,100 | 3,450 |

| 6202 | 15 | 35 | 11 | 0.6 | 7,650 | 3,750 |

| 6202-2RS | 15 | 35 | 11 | 0.6 | 7,650 | 3,750 |

| 6202ZZ | 15 | 35 | 11 | 0.6 | 7,650 | 3,750 |

| 6302 | 15 | 42 | 13 | 1 | 11,400 | 5,450 |

| 6302-2RS | 15 | 42 | 13 | 1 | 11,400 | 5,450 |

| 6302ZZ | 15 | 42 | 13 | 1 | 11,400 | 5,450 |

| 6003 | 17 | 35 | 10 | 0.3 | 6,000 | 3,250 |

| 6003-2RS | 17 | 35 | 10 | 0.3 | 6,000 | 3,250 |

| 6003ZZ | 17 | 35 | 10 | 0.3 | 6,000 | 3,250 |

A wide range of applications:

• agriculture and forestry equipment

• automotive and industrial gearboxes

• automotive and truck electric components, such as alternators

• electric motors

• fluid machinery

• material handling

• power tools and household appliances

• textile machinery

• two Wheeler.

Our Bearing Advantage:

1.ISO Standard

2.Bearing Small order accepted

3.In Stock bearing

4.OEM bearing service

5.Professional:20 years manufacture bearing

6.Customized bearing, Customer’s bearing drawing or samples accepted

7.Competitive price bearing

8.TT Payment or Western Union or PayPal

Our Company

| Packaging Details | 1 piece in a single box 50 boxes in a carton 20 cartons in a pallet |

| Nearest Port | ZheJiang or HangZhou |

| Lead Time | For stock parts: 1-5 days. If no stock parts: <200 pcs: 15-30 days ≥200 pcs: to be negotiated. |

FAQ

1.How do you make our business long-term and good relationship?

– We keep good quality and competitive price to ensure our customers benefit ;

– We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

2.Do you test all your goods before delivery?

– Yes, we have 100% test before delivery

3.What products does your company supply?

– Auto Bearings (Wheel Bearings, Wheel Hub Bearings, Clutch Bearings, Belt Tensioners and Water Pump Bearings etc. )

-Industrial Bearings (Deep Groove Ball Bearings, Tapered Roller Bearings and Pillow Block Bearings).

Types of V-Belts and Their Properties

A v-belt’s inside length and pitch are determined by measuring along the bottom side. The included angle of a v-belt is measured from its flanks when it is extended. Most v-belt sections are 40 degrees. There are different types of v-belts, and the dimensions of each are standardized by different organizations. This article will introduce the different types of v-belts and their properties.

Notched v-belts reduce bending stress

Notched V-belts reduce bending stress by reducing the axial length of the belt by 2 or more notches. These notches are characterized by different profiles, which differ in the pitch angle and the inside length. ISO and DIN standards are followed by the manufacturers of these belts. Notched v-belts are used on industrial machinery in countries other than the US.

Compared to the standard V-belts, notched ones are designed to resist bending stress better and offer better heat dissipation. They also last longer and run cooler than standard V-belts. Furthermore, they are about 2 percent more energy efficient than their standard counterparts. Therefore, notched V-belts are a viable replacement for standard V-belts.

Notched V-belts are commonly used in industrial applications because of their low price, ease of installation, and availability of many sizes. Another advantage of notched V-belts is that they provide more wedging force and higher load capacity. Notched V-belts have a wider v-groove than flat ones, which makes them more effective for heavy-duty applications.

Notched V-belts also provide better traction. They reduce bending stress, which is beneficial for preventing fatigue and tearing of v-belts. Additionally, v-belts can be installed in an existing equipment to add more performance. And with proper maintenance and installation, notched V-belts will provide trouble-free service for many years to come.

Ribbed v-belts reduce heat dissipation

Various kinds of v-belts are available for varying applications. The more popular types are the fractional horsepower and the double-V. Fractional horsepower v-belts are designed for light-duty applications, such as machine shop equipment and household appliances. The common sectional names are 2L, 3L, 4L, and 5L. The L in each of these belts refers to the top width of the belt, multiplied by 1 eighth inch.

Unlike conventional belts, ribbed v-belts are flexible, making them ideal for use in vibrating loads. They reduce heat dissipation and can be ordered in single or multiple sets to match your application. However, ribbed v-belts should not be mounted on deep-groove sheaves, as this can cause the belt to turn over. If you use deep-groove sheaves, the risk of rupture is very high. Deep-groove sheaves can also cut banded belts. Extremely worn sheaves can also cause the belt to rip.

The 2 types of ribbed v-belts differ in their construction and application. While both types have trapezium cross-sections, they are similar in that they are made of polyurethane or other durable materials. Ribbed v-belts have an additional layer of fabric on the elastomer core for reduced noise and better heat dissipation.

Ribbed v-belts are available in a variety of sizes, including trough v-belts. Their cross-sections are categorized by their top and bottom widths and depths. The included angle of most v-belt sections is approximately 40 degrees. Different types of v-belts have different cross-sections, and these cross-sections are standardized by various organizations.

As the load increases, a ribbed v-belt will wedge into the groove and decrease the amount of friction needed to maintain the correct torque. Flat belts can track off the pulleys due to friction. However, V-belts are more stable and require less width than flat belts. The main advantage of ribbed v-belts is their increased efficiency.

The global-local finite-element model is also used to calculate the maximum and minimum J-integrals during a belt’s running cycle. The data is then used to evaluate the durability of ribbed v-belts in various applications. The numerical models used for the calculations involve a ribbed V-belt with 5 full ribs.

Cogged v-belts increase lateral rigidity to reduce belt whip

Cogged v-belts are designed for maximum performance and durability on even the harshest drive systems. These belts are made from high-modulus polyester cords that resist hardening and stretch and provide superior balance and strength. They also feature raw-edge sidewalls to reduce slip and drive vibration. In addition, they have specially-formulated rubber compounds for oil resistance. CZPT Cog-Belt offers substantial savings in downtime, energy consumption and horsepower.

A double cogged v-belt combines the benefits of cogged and double vee-belts. Its bonded reinforced tie band offers enhanced flexibility and reduces belt whipping in multiple-belt drives. Double cogged v-belt dimensions vary depending on the standards of the manufacturer. Regardless of the type, you’ll want to use a belt that is aligned correctly.

Standard v-belts are also known as wrapped or raw edge v-belts. Wrapped V-belts feature fabric covers above and beneath the cord to increase lateral rigidity and reduce belt whip. Cogged V-belts also have fabric covers to prevent wear on the core and increase the belt’s operating temperature. They’re ideally suited for applications that require high-temperature operation.

Cogged V-belts can significantly decrease energy consumption and improve power transmission capabilities. They also have a bias-cut cover stock that provides axial and lateral stability while preserving the cord integrity. A fiber loaded cogged construction offers optimum flexibility while minimizing heat buildup. It can be installed on any type of drive, including chain conveyors and industrial-grade machines.

The two-layer tie-band permanently bonds multiple belts together. This provides maximum cord support, heavy shock absorption, and stability. The belts are also engineered with patented banding processes that eliminate belt turnover and distribute load evenly across the drive. CZPT Cog-Band Belts minimize belt whip and provide stability. They also minimize belt turnover and rollover in heavy-duty industrial applications.

A classic v-belt is the most common and economical belt. Its nominal dimensions are 1/2″ to 1-11/2″ wide and 16″ to 400 inches long. The width is usually 40 degrees. Different organizations use different cross-sections to classify v-belts. The following table provides a general comparison of the 2 types. The Cogged V-Belt is designed to reduce belt whip by increasing the lateral rigidity of the belt.

Cogged v-belts provide superior environmental resistance

The patented design of the Dayco V-Belt provides maximum power transmission while combining the benefits of a cogged belt and raw-edge construction. The belt’s top cogged design helps increase air flow around it, preventing deterioration and extending its useful life. The belt’s three-ply design features neoprene impregnated fabric for superior durability and a specially-formulated polyester cord for increased strength and stability.

A variety of v-belts are available, with cogged and notched versions presenting unique characteristics. Cogged V-belts are more flexible than uncogged versions and feature ‘X’-shaped grooves for enhanced heat dissipation. Cogged V-belts are interchangeable with conventional v-belts, although their ‘X’ design is most common. Hexagonal v-belts are a popular option for applications where traction is needed.

Another type of Cogged V-belt is designed specifically for outdoor power equipment. This v-belt is brown, with smooth clutching covers. Its aramid cord is very strong and provides superior durability in adverse conditions. Cogged V-belts can withstand severe shock loads and are therefore ideal for outdoor power equipment. Furthermore, they offer superior environmental resistance, minimal stretch, and a long service life.

A Cogged V-belt is composed of tensile cords that are supported by a rubber stock. Different manufacturers use different synthetic rubber stocks for this purpose. These materials help to extend the belt’s operating temperature range and resist premature failure. In addition to tensile cords, the belt’s body is covered with a fabric cover. The fabric is treated to form a chemical bond with the core materials, which allows it to withstand constant bending.

China Good quality Bearings for Conveyor Agricultural Machinery Diesel Hydraulic Press Excavator Spare Parts Textile Machine Engraving Machine Concrete Deep Groove Ball Bearing with Best Sales

Product Description

QUICK OVERVIEW

| Model | Deep Groove Ball Bearing |

| Greese/Oil | As your requirement, such as open, z,zz,rz, 2rz,rs, 2rs, and so on. |

| Vibration | Z1/V1,Z2/V2,Z3/V3 |

| Tolerance codes | ABEC-1, ABEC-3, ABEC-5, ABEC-7 |

| Internal clearance codes | C0, C2, C3, C4, C5 |

| Snap ring | N, NR |

| Quality level | Reach the same level as Japanese and European bearings, P0 P2 P4 P5 P6.. |

| Feature | Low voice, High speed, Low friction, long service life |

| Application | Pharmaceutical equipment, medical equipment, textile machinery and accessories, knitting machines, weaving machines, spinning equipment, textile accessories, non-woven fabric machinery, textile equipment, machinery, metal, mold, automotive electronics, electrical, instrumentation, military, aviation aerospace, plastics and rubber industry, medical and other fields. |

| Package | 1,barreled package+outer carton+pallets 2,single box+outer carton+pallets 3,tube package+middle box+outer carton+pallets 4,According to your’s requirement |

| Details | We have a complete process for production and quality assurance to make sure our products can meet your requirement. 1.Assembly 2.Windage test 3.Cleaning 4.Rotary test 5.Greasing and gland 6.Noise inspection 7.Appearance inspection 8.Rust prevention |

Deep groove ball bearings are the most representative structure in rolling bearings and have been widely used in many industries, such as cars, compressors, construction, electric motors, food industry, home appliances, etc. They are suitable for high or even extremely high-speed operation, and very durable, and need not be maintained regularly. This kind of bearing has a small friction coefficient, high limit speed. Widely used in industrial machinery, automobile, electrical system.

Application and popular suitable models:

1.Motorcycle rear wheel bearing: 63032RS, 6302 2RS

2.High-speed ball bearing for electric tools: 628ZZ, 688ZZ

3.Bearing for electric motor: 6204 2RS, 6205 2RS

4.Skateboard rubber roller bearings: 608 2RS, 6072RS, 6092RS, 6282RS

5.Stainless steel deep groove ball bearings for the food industry: S6900 2RS, S6901 2RS

6.Ceiling fan bearing: 6202 ZZ, 6203 ZZ

7.Thin wall deep groove ball for sweeper: 6900, 6800 series

Pictures

Model List (Please contact with us for more models)

| Product | Bore Dia (d) (mm) | Outer Dia (D) (mm) | Width (B) (mm) | Radius (min) (rs) (mm) | Dynamic Load Rating (Cr) (N) | Static Load Rating (Cor) (N) |

| 6000 | 10 | 26 | 8 | 0.3 | 4,550 | 1,950 |

| 6000-2RS | 10 | 26 | 8 | 0.3 | 4,550 | 1,950 |

| 6000ZZ | 10 | 26 | 8 | 0.3 | 4,550 | 1,950 |

| 6200 | 10 | 30 | 9 | 0.6 | 5,100 | 2,400 |

| 6200-2RS | 10 | 30 | 9 | 0.6 | 5,100 | 2,400 |

| 6200ZZ | 10 | 30 | 9 | 0.6 | 5,100 | 2,400 |

| 6300 | 10 | 35 | 11 | 0.6 | 8,100 | 3,450 |

| 6300-2RS | 10 | 35 | 11 | 0.6 | 8,100 | 3,450 |

| 6300ZZ | 10 | 35 | 11 | 0.6 | 8,100 | 3,450 |

| 6001 | 12 | 28 | 8 | 0.3 | 5,100 | 2,400 |

| 6001-2RS | 12 | 28 | 8 | 0.3 | 5,100 | 2,400 |

| 6001ZZ | 12 | 28 | 8 | 0.3 | 5,100 | 2,400 |

| 6201 | 12 | 32 | 10 | 0.6 | 6,800 | 3,050 |

| 6201-2RS | 12 | 32 | 10 | 0.6 | 6,800 | 3,050 |

| 6201ZZ | 12 | 32 | 10 | 0.6 | 6,800 | 3,050 |

| 6301 | 12 | 37 | 12 | 1 | 9,700 | 4,200 |

| 6301-2RS | 12 | 37 | 12 | 1 | 9,700 | 4,200 |

| 6301ZZ | 12 | 37 | 12 | 1 | 9,700 | 4,200 |

| 6002 | 15 | 32 | 9 | 0.3 | 5,600 | 2,850 |

| 6002-2RS | 15 | 32 | 9 | 0.3 | 5,600 | 2,850 |

| 6002ZZ | 15 | 32 | 9 | 0.3 | 8,100 | 3,450 |

| 6202 | 15 | 35 | 11 | 0.6 | 7,650 | 3,750 |

| 6202-2RS | 15 | 35 | 11 | 0.6 | 7,650 | 3,750 |

| 6202ZZ | 15 | 35 | 11 | 0.6 | 7,650 | 3,750 |

| 6302 | 15 | 42 | 13 | 1 | 11,400 | 5,450 |

| 6302-2RS | 15 | 42 | 13 | 1 | 11,400 | 5,450 |

| 6302ZZ | 15 | 42 | 13 | 1 | 11,400 | 5,450 |

| 6003 | 17 | 35 | 10 | 0.3 | 6,000 | 3,250 |

| 6003-2RS | 17 | 35 | 10 | 0.3 | 6,000 | 3,250 |

| 6003ZZ | 17 | 35 | 10 | 0.3 | 6,000 | 3,250 |

A wide range of applications:

• agriculture and forestry equipment

• automotive and industrial gearboxes

• automotive and truck electric components, such as alternators

• electric motors

• fluid machinery

• material handling

• power tools and household appliances

• textile machinery

• two Wheeler.

Our Bearing Advantage:

1.ISO Standard

2.Bearing Small order accepted

3.In Stock bearing

4.OEM bearing service

5.Professional:20 years manufacture bearing

6.Customized bearing, Customer’s bearing drawing or samples accepted

7.Competitive price bearing

8.TT Payment or Western Union or PayPal

Our Company

| Packaging Details | 1 piece in a single box 50 boxes in a carton 20 cartons in a pallet |

| Nearest Port | ZheJiang or HangZhou |

| Lead Time | For stock parts: 1-5 days. If no stock parts: <200 pcs: 15-30 days ≥200 pcs: to be negotiated. |

FAQ

1.How do you make our business long-term and good relationship?

– We keep good quality and competitive price to ensure our customers benefit ;

– We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

2.Do you test all your goods before delivery?

– Yes, we have 100% test before delivery

3.What products does your company supply?

– Auto Bearings (Wheel Bearings, Wheel Hub Bearings, Clutch Bearings, Belt Tensioners and Water Pump Bearings etc. )

-Industrial Bearings (Deep Groove Ball Bearings, Tapered Roller Bearings and Pillow Block Bearings).

How to Repair a Timing Belt Tensioner

Your timing belt tensioner is a critical component of your vehicle’s drivetrain. Too little tension, for example, will cause the belt to slip, and too much tension can overload shaft bearings, leading to premature failure. If you notice that your belt tensioner is not working properly, you should immediately visit a mechanic. Corrosion from road splash, dirt, mud, or other debris can jam the tensioner housing. To avoid this, make sure that you replace your timing belt tensioner as soon as possible.

Symptoms of a bad belt tensioner

If you’ve ever wondered what signs indicate a bad belt tensioner, look no further than your vehicle’s engine. Worn belts or a broken tensioner can cause an irritating squealing noise, as well as the belt to slip. Even worse, a bad tensioner can cause water to enter the belt and pulley, resulting in water damage. A worn tensioner is usually the culprit of the noise, but there are also other warning signs that a belt is in trouble.

Your vehicle’s engine may start to run poorly or even squeal when you turn the key. Similarly, your engine may fail to start at all, or the check engine light may illuminate. The belt may also start to wear out in an unusual pattern. These signs indicate that the tensioner is in need of replacement. If you notice 1 or more of these signs, get your car checked right away.

To check the condition of the tensioner, remove the drive belt and observe the pulley. You may notice rust dripping or bleeding at the mounting bolts, which are the most common signs of a bad tensioner. If you can’t remove the drive belt, check the pulley by rotating it. If you feel resistance, the pulley is likely worn or slack.

Failure of the belt tensioner will also cause other parts of the car to fail. If a bad belt tensioner isn’t fixed quickly, you might not be able to use the vehicle properly. You could end up breaking your car’s engine, losing power steering, and possibly even the water pump. If your car is not running right, you could be stuck in the middle of nowhere. Even if the alternator doesn’t work, you’ll still have a malfunctioning power steering system and a dead AC system.

A broken timing belt tensioner can cause strange noises or a no-start condition. These noises and symptoms are signs of a bad belt tensioner, and you’ll have to replace it ASAP. If you don’t know what symptoms mean, don’t hesitate to take your car to a mechanic. You’ll be surprised how easy it is to check this vital component and save yourself a bunch of money.

Components of a belt tensioner

The components of a belt tensioner assembly consist of 4 key components. The clearance between the pulley and the base is critical to the tensioner’s operation. If the tensioner is installed incorrectly, the spring can break and cause severe injury. The spring’s preload and powerful force make it difficult to service the unit safely. These parts are non-serviceable. If you are unsure of how to repair your tensioner, contact an authorized mechanic.

The components of a belt tensioner drive are shown in FIG. 2. The rotor shaft is connected to the drive screw, while the second transmission is connected to the gear shaft. The rotor and gear shaft are in parallel with each other. The gear shaft and worm wheel are connected to the belt tensioner drive. In other words, the belt tensioner drive is located in the B-pillar of the motor vehicle.

A belt tensioner may be equipped with a drive shaft and electric motor. The drive shaft may also contain a worm gear or worm wheel. The drive shaft also has an intermediate gearbox. Once the tensioner is set, it is ready to move to its safe-position position. It is a relatively simple and inexpensive replacement for your belt. When replacing a multi-ribbed belt, be sure to replace the tensioner along with the belt. Gates recommends replacing all wear parts at once.

In the event of a faulty drive belt tensioner, the belt will not stay taut. The pulley can wobble and cause the belt to fray. In addition to this, the bearings can cause a loud squealing noise. In this case, the accessory motors will continue to run, while the belt itself will not. Therefore, replacing the timing belt tensioner is an important part of maintaining the car.

In some systems, the belt tensioner uses a worm gear as the first gear. This results in rolling engagement of the screw’s teeth. This reduces noise and vibrations, while maximizing the efficiency of the belt tensioner drive. Additionally, a worm gear can eliminate the need for additional parts in belt tensioners. While this may not be practical in all instances, it is a good choice for space-constrained environments.

Repair options for a timing belt tensioner

A timing belt tensioner is an essential part of an automobile’s timing chain and is responsible for ensuring proper timing. Proper alignment of timing marks is essential to the proper operation of the engine, and improper alignment may lead to damage to the engine. To repair a timing belt tensioner, there are several repair options available. First, you need to remove the engine cover. You can then remove the timing belt tensioner by loosening the pulley using a ratchet or breaker bar.

When the timing belt isn’t properly tensioned, the engine will misfire. The engine misfires when the valve opens and the pistons rise at the wrong time. When this happens, the timing belt cannot properly grip the gears and the engine will not function. If this part fails, you’ll have to replace the whole timing chain. However, if you are handy with tools, you can easily replace the entire timing belt tensioner yourself.

If your timing belt tensioner is out of alignment, you should replace it. If you’re not sure whether it needs to be replaced, check it with a professional and learn the details of the repair. The timing belt tensioner is the most critical part of the engine, so it’s important to know about it. Otherwise, your car won’t run as well as it could. Repair options for a timing belt tensioner will vary depending on the severity of the problem and how much damage it has done.

While there are several repair options for a timing belt tensioner, the average cost of replacement is $364 to $457, and this doesn’t take into account any tax or fee you may be charged. DIY repair methods will usually cost you $50 to $150, and you’ll likely save a lot of money in the process. However, you need to remember that you may be unable to do the job yourself because you don’t know how to use the proper tools and equipment.

While it is not difficult to replace a timing belt tensioner on your own, you should know that you’ll need to remove other parts of the engine as well as special tools to make the repair properly. This is an advanced repair job and requires a great deal of skill. If you’re new to home car repair, you may not want to attempt it yourself. There are many other options, such as hiring a mechanic.

Installation instructions

While there are no universal installation instructions for belt tensioners, the manufacturer of your car may provide detailed instructions. Before attempting to replace your tensioner, read the manufacturer’s recommended procedures carefully. To install a new tensioner properly, unload the old 1 and take a picture or sketch of how the belt should be routed. Once the old tensioner is out, follow the manufacturer’s torque specifications. Make sure to unload and remove the belt from the tensioner, and follow the manufacturer’s torque specifications to install the new one.

If your car comes with a manual belt tensioner, you can follow the instructions. The manual will have a corresponding guide for installation. When installing a belt tensioner, make sure the manual clearly states the static tension for your particular model. Check that it is in line with the engine relief to ensure proper belt tension. You can then use a 6mm allen key to turn the tensioner clockwise and counterclockwise. Once it is in position, release the tensioner to operate. The belt tensioner should now apply the proper tension to your belt.

Before installing a new belt tensioner, make sure you read the manual completely. You should follow these steps carefully to avoid any problems with the tensioner. If the tensioner has failed, you must replace it immediately. A new belt tensioner will help you ensure proper performance of your accessory belt drive system. If you are installing a new multi-ribbed belt, you should replace the tensioner as well. However, it is important to note that replacing the belt tensioner is a complicated process and requires a mechanic to be able to safely remove the belt from the engine.

To install a second stage drive belt, walk the belt onto the input drive and generator. Ensure that the belt is seated properly in the grooves of the pulleys. Next, replace the input drive belt and right and left Drive Disk covers. Test the machine to ensure that it is working properly. If it doesn’t, replace the original drive belt. After installing the new belt, you may want to read the manual again to make sure it is in perfect condition.

China Standard Suzuki Carry Spare Parts 12810-73003 Timing Belt Pulley Bearing Jpu52-128jf434 Vkm76103 1281084000 Gt377.05 Factory Price with Great quality

Product Description

Quick view:

| Name | Timing Belt Pulley Bearing 12810-73 | VKM182 | Lada (Vaz) | |

| B | VKM21031 | CR1681 | F-853 | Audi / VW |

| 074109243A | VKM21041 | CR3123 | F-210963.1 | Audi / VW |

| 57109243D | VKM21045 | CR3142 | F-225766.1 | Audi / VW |

| 078109244F | VKM21052 | CR3129 | Audi / VW | |

| 036109244D | VKM21120 | CR3145 | F-231219 | Audi / VW |

| 036109181A | VKM21121 | CR3148 | F-231220 | Audi / VW |

| 038109244H | VKM21130 | CR3 | Audi / VW | |

| 038109244J | VKM21147 | CR3495 | F-239652 | Audi / VW |

| 078109244G | VKM21201 | CR1643 | F-123658 | Audi / VW |

| 7553565 | VKM22151 | CR1645 | F-11571.1 | Fiat / Lancia |

| 60811487 | VKM22153 | CR1834 | F-123650 | Alfa Romeo |

| 7540301 | VKM22160 | CR1668 | F-123624 | Fiat / Lancia |

| 60652129 | VKM22173 | CR1828 | F-123653 | Alfa Romeo |

| 7763644 | VKM22174 | CR1896 | F-123803 | Alfa Romeo |

| 6571624 | VKM22177 | CR3265 | F-231098.2 | Fiat / Lancia |

| 551871.3 | Fiat / Lancia | |||

| 4740847 | VKM22380 | CR1666 | F-220324 | Fiat / Lancia |

| 4740846 | VKM22385 | CR1665 | F-220323 | Fiat / Lancia |

| 6571304 | VKM22510 | CR1874 | F-123804 | Alfa Romeo |

| 5952181 | VKM22630 | CR1657 | F-45605 | Fiat / Lancia |

| 94057171 | VKM23120 | CR1827 | F-122124 | Fiat / Lancia |

| 830.46 | VKM23122 | CR3590 | F-122124.2 | P-eugeot |

| 830.2 | VKM23130 | CR3279 | F-122574 | P-eugeot |

| 2S6Q6M250AA | VKM23140 | CR3511 | F-123906.4 | Ford |

| 830.42 | VKM23230 | CR3410 | P-eugeot | |

| 21215- 1 |

Lada (Vaz) | |||

| 9615923380 | VKM23241 | CR1887 | F-122216 | Fiat / Lancia |

| 830.29 | VKM23244 | CR3.5 | Fiat / Lancia | |

| VKM233 | Fiat / Lancia | |||

| 96FF6K254DA | VKM241.2 | Ford | ||

| 89FF6K254CB | VKM24104 | CR1875 | F-49229.1 | Ford |

| 97FF6K254DA | VKM24107 | CR3094 | F-140845.1 | Ford |

| 6635942 | VKM24210 | CR1862 | F-145712 | Ford |

| 6744307 | VKM24211 | CR1864 | F-145713 | Ford |

| 978M6M250AA | VKM24212 | CR31 | Ford | |

| 1 0571 71 | VKM24213 | CR3099 | F-233879 | Ford |

| 157142 | VKM24214 | CR3101 | F-231338 | Ford |

| 9 0571 731 | VKM25150 | CR1898 | F-218740.1 | O-pel / GM |

| 9128739 | VKM25152 | CR1899 | F-218741.1 | O-pel / GM |

| 90180131 | VKM252 | O-pel / GM | ||

| 90264571 | VKM25201 | CR1837 | F-22 | O-pel / GM |

| 636418 | VKM25202 | CR1880 | F-224963 | O-pel / GM |

| 94106 | O-pel / GM | |||

| Y701-12-730 | VKM25210 | CR1683 | F-123806 | Mazda |

| 5636425 | VKM25212 | CR1801 | F-218108.4 | O-pel / GM |

| 636416 | VKM25213 | CR1803 | F-224966 | O-pel / GM |

| 924 | O-pel / GM | |||

| 150 | VKM26571 | CR3229 | F-123778 | R-enault |

| 7701349659 | VKM261 | O-pel / GM | ||

| 770571489 | VKM26102 | CR1866 | F-39990 | R-enault |

| 82 | R-enault | |||

| VKM26114 | CR3226 | F-123733 | R-enault | |

| 77 | R-enault | |||

| 305 | VKM26123 | CR3231 | F-123732 | R-enault |

| 9110639 | VKM26125 | CR3226 | F-123733 | O-pel / GM |

| 77 | R-enault | |||

| 77 | R-enault | |||

| 775718626 | VKM26310 | CR3208 | F-123781 | R-enault |

| VKM265 | R-enault | |||

| MWM 38 | O-pel / GM | |||

| 7439146377 | VKM26602 | CR3362 | F-224696 | R-enault |

| ETC8560 | VKM27404 | CR3325 | F-14 | Audi / VW |

| 57145276A | VKM31 | Audi / VW | ||

| 078903341J | VKM31571 | CR3124 | F-225712 | Audi / VW |

| M | VKM31571 | CR3733 | Audi / VW | |

| 59145276 | VKM31039 | CR3469 | Audi / VW | |

| 57103341A | VKM31041 | CR3245 | F-228319 | Audi / VW |

| 074145278F | VKM31043 | CR3133 | F-231228 | Audi / VW |

| 5826571 | VKM31059 | CR3154 | F-23 0571 | Audi / VW |

| 32145276 | VKM31207 | CR3483 | F-551814 | Seat |

| 73501924 | VKM32 | Alfa Romeo | ||

| 46440604 | VKM32- 3 | Alfa Romeo | ||

| 6571349 | VKM32 | Alfa Romeo | ||

| 46441096 | VKM32015 | CR1460 | F-1238 | Fiat / Lancia |

| 6571427 | VKM32030 | CR1492 | Fiat / Lancia |

ZheJiang Mighty (SI Bearing)are providing deep groove ball bearing, tapered roller bearing, pillow block bearing, spherical roller bearing, angular contact ball bearing, needle bearing, self-aligning ball bearing, linear bearing, wheel hub bearing, hub unit, clutch release bearing, belt tensioner, etc.

Our Bearing Advantage:

1.Free Sample bearing

2.ISO certified

3.Bearing Small order accepted

4.In Stock bearing

5.OEM bearing service

6.Professional: Over 20 years manufacture bearing

7.Customized bearing, Customer’s bearing drawing or samples accepted

8.Competitive price

9.TT Payment, Paypal, Alibaba payment, Trade Assurance Order

FAQ:

Q: Can you help with my own brand?

A: Sure. We can make for your brands. We can mark your brand name and use your box’s design with the legal authority letter.

Q: How can I make an inquiry?

A: You can contact us by email, telephone, WhatsApp, , etc.

Q: How long can reply inquiry?

A: Within 24 hours.

Q: Which Service you can provide?

A: 1. Help customers to choose correct bearing

2. Professional team, make your purchase easily

Q: When are you going to deliver?

A: Sample: 5-15 business days after payment is confirmed.

Bulk order:15-60 workdays after deposit received…

Q: What’s your delivery way?

A: By sea, by air, by train, express as your need.

Q: What are your terms of delivery?

A: EXW, FOB, CFR, CIF, DAP, etc.

Q: Can you support the sample order?

A: Yes, we can supply the sample if we have parts in stock, but the customer has to pay the sample payment(according to the value of the samples) and the shipping cost.

Q: What are you going to do if there has a claim for the quality or quantity missing?

A: 1. For quality, during the warranty period, if any claim for it, we shall help customer to find out what’s the exactly problem. Using by mistake, installation problem, or poor quality? Once it’s due to the poor quality, we will arrange the new products to customers.

2. For missing quantities, there have 2 weeks for claiming the missing ones after receiving the goods. We shall help to find out where it is.

Tips For Replacing a Belt Tensioner

When replacing a serpentine belt or automatic tensioner, you will need a special tool. This tool has a long, flat extension handle that allows you to place a socket onto the bolt and flats on the tensioner arm. The following are some tips to follow when replacing the belt or tensioner on your vehicle. To replace your belt or tensioner, you should start by checking the tensioner’s lubrication.

Serpentine belt

If you notice that the power steering or air conditioning are not working, you should check the serpentine belt tensioner. A malfunctioning serpentine belt tensioner can lead to a host of other issues. The belt may stretch, which can be caused by several factors. Over time, serpentine belt tensioners can also get worn down. Additionally, they can have a variety of other problems, including rust or dirt in the housing.

You can replace your serpentine belt by following the instructions found on your vehicle’s manual. Some tensioners attach to the engine via a single bolt. To remove and replace the belt, remove the old unit and the retaining bolt. Locate the locking pin in the engine and place the new tensioner over it. Use a torque wrench or hand tool to tighten the bolts. When installing the new tensioner, be sure to line up the mounting bolt holes with the mounting bolts. Once the tensioner is installed, test the tension by ensuring that the gauge is above the ribs. If it slides down, it is time to replace the tensioner.

Before you begin the process of replacing your serpentine belt, be sure to park your vehicle in a level area. Turn off the engine and chock both rear wheels before starting the process. Using a diagram from your vehicle’s repair manual can make the process easier, especially if you are a beginner. You can draw it in your hand, or refer to a repair manual to find out the exact location of the tensioner pulley.

If you notice that the belt is slipping or squealing while driving, it may be time to replace the serpentine belt tensioner. A worn-out belt can cause the belt to slip and can cause power steering, air conditioning, and alternator malfunctions. You should also check the belt tensioner regularly. The motor may stall or make a loud noise. These are all signs of worn-out serpentine belt.

A serpentine belt uses less space in the engine than a V-belt. It also provides more tension for the serpentine belt, which prevents it from running hot and squealing. Serpentine belts are manufactured to last for several hundred thousand miles. They are a must-have item for your car! So be sure to keep it maintained and properly adjusted! Then, you can be sure to have your car running smoothly and safely.

If you notice any of these symptoms, you should replace your serpentine belt tensioner. A serpentine belt tensioner is a simple self-10sioning device that is mounted on the front of the engine. These devices are usually easy to replace and are not complicated to install. You can find 1 at any parts store or online. When the time comes to replace your serpentine belt, don’t hesitate to get the parts you need from a local auto part store.

Idler pulley

The idler pulley and the belt tensioner are essential components of your car’s drivetrain. If any 1 of them fails, all of them must be replaced. This is because they were manufactured at the same time and most likely have the same number of miles on them. As a result, they can all fail within a few thousand miles of each other. Here are some of the symptoms that you should look for when inspecting your idler pulley or belt tensioner.

Idler pulleys are a common part of most cars. They play a vital role in the operation of the belt system by directing the belt’s path and providing additional contact with the pulley. The idler pulley is also responsible for turning the cooling fan in an air-cooled Corvair engine. Because of these functions, idler pulleys are often replaced with idlers that differ in size.

Idler pulleys are small, 2 to 4 inches in diameter and mounted on the front of the engine block. Their purpose is to create a constant amount of tension on the drive belt. When the idler pulley is worn out, the accessory drive belt may experience excessive vibration and squealing noises. You may wish to replace it as soon as possible. You can do so at AutoZone.

A worn or damaged idler pulley will require a replacement. The belt itself will not fall off the car unless the idler pulley is damaged. A squealing sound can be a sign of a broken spring. Alternatively, a mechanic can recommend a replacement based on the condition of the idler pulley. In most cases, idler pulleys are more durable than the belts and are therefore recommended for replacement.

You can also notice that the idler pulley is slipping or causing excessive noise. Its constant rotation wears the idler pulley and reduces the tension of the belt. This causes the belt to slip and may even tear off the engine. Ultimately, this could result in stalling. And if you notice the engine belt squealing or making excessive noises, you should consider replacing it.

An idler pulley for a belt tensioner are often confused. Though both of them are used in the same application, they differ in many ways. The tensioner is the 1 that receives pressure from the belts and moves them. The idler pulley is not attached to an adjustable bolt, and it can cause unusual noises. It might even make squealing or odd noises.

Spring tensioner

A spring belt tensioner is a solution to a loose belt. It features a strong torsion spring that reduces slack. These devices are designed to fit up to 6mm wide belts. They are highly reliable and durable. They are also suitable for applications where the engine speed is often fluctuating. Here’s how you can choose the best 1 for your vehicle. The spring in the tensioner should be in the proper position to keep the belt taut and free of slippage.

The RunRight tensioner is a durable, high-quality product that uses aluminum alloy. Its elastomeric inserts rely on highly elastic natural rubber for good shape memory and durability. Spring tensioners are easy to install and maintain. They are designed for both axial and helical drives. They feature detailed technical drawings and 3-D models to help you determine the best 1 for your application. To choose a spring tensioner, visit our website.

A worn bushing in the tensioner pulley or a loose pivot arm can result in excessive noise, vibration, and premature belt failure. In addition, worn springs cannot maintain proper tension. Over time, they lose tension. The pulley arm itself can also become damaged, preventing it from rotating properly. If these problems occur, you’ll need to replace the spring tensioner. If you don’t see any signs of wear, check your mounting bracket and tensioner.

A worn pivot bushing can cause the tensioner arm to misalign, leading to excessive back and forth sway. It may also cause the tensioner to jam, which means the belt is too long or too short. If you notice excessive wobble, you should replace the spring tensioner. A faulty tensioner may also be causing excessive oscillation in the pulley. To determine if the spring tensioner is too weak or jammed, check the belt’s length by using a breaker bar or socket with a long handle ratchet.

When it’s time to replace your serpentine belt, don’t forget to replace the belt tensioner. The tensioner protects other components from premature failure. It is a relatively inexpensive repair. It should be replaced as part of a larger multi-ribbed belt. It also provides protection for other components of the drive system. In addition to its protection and performance, the tensioner is inexpensive and relatively easy to replace.

It’s vital to check the tensioner and idler pulleys to make sure the system is aligned properly. If they don’t align, the belt will slip and cause premature wear. Alternatively, the tensioner may have too much tension, overloading the shaft bearings and causing premature failure in other parts. You should also check the idler pulleys for noise as well, since these are engine-driven accessories.