Product Description

Product data

|

Product Name |

Perfectrail 5 |

|

Position |

Front |

|

Car Model |

For CZPT Daily I Van 40-8 V For Fiat Ducato Bus 230 2.8 D |

|

Weight |

OEM Standard |

|

Package Size |

OEM Standard |

|

MOQ |

1 piece if we have them in stock, 50 pieces for production. |

|

Warranty |

12 Months |

|

Delivery Time |

7-25 Days |

|

Package |

Neutral, Perfectrail or Customized Packing is acceptable Neutral packing. Neutral box and brown cartons. Pallet is also available. |

|

Our Advantage |

1. The same size as original one. 2. Lower MOQ is acceptable with more models. |

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hours Service |

|---|---|

| Warranty: | 12 Months |

| Quality: | High-Quality |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the reliability and durability aspects of belt tensioners in ensuring consistent belt tension?

Belt tensioners play a crucial role in ensuring consistent belt tension in belt-driven systems. The reliability and durability of belt tensioners are essential factors in maintaining optimal belt performance and preventing issues such as slippage, excessive wear, or premature failure. Here’s a detailed explanation of the reliability and durability aspects of belt tensioners in ensuring consistent belt tension:

- Design and Construction:

- Load Capacity:

- Resistance to Wear and Fatigue:

- Corrosion and Contamination Resistance:

- Temperature Stability:

- Lubrication and Friction Management:

- Maintenance and Inspection:

The design and construction of belt tensioners are critical for their reliability and durability. High-quality materials, precision engineering, and robust construction techniques are employed to ensure that tensioners can withstand the forces and loads encountered in belt-driven systems. The design should incorporate features that minimize stress concentrations, prevent premature wear, and provide long-lasting performance.

Belt tensioners must have adequate load capacity to handle the tension forces exerted by the belt system. A properly sized tensioner will allow for the consistent application of the desired tension level, even under varying loads and operating conditions. Insufficient load capacity can lead to insufficient tension, resulting in belt slippage, reduced power transmission, and potential system failure.

Reliable belt tensioners are designed to resist wear and fatigue over extended periods of operation. They should be able to withstand the continuous movement and contact with the belt without experiencing excessive wear or deformation. High-quality materials, surface treatments, and lubrication mechanisms may be employed to enhance the tensioner’s resistance to wear and fatigue.

Belt tensioners in certain environments may be exposed to corrosive substances, moisture, or contaminants such as dust and debris. To ensure reliability and durability, tensioners can be designed with corrosion-resistant materials, protective coatings, or sealing mechanisms. These features help prevent the degradation of tensioner components and maintain their performance in challenging operating conditions.

Temperature fluctuations can affect the performance and longevity of belt tensioners. Reliable tensioners are engineered to withstand the temperature extremes commonly encountered in industrial or automotive applications. They may incorporate materials with high-temperature resistance or thermal management mechanisms to maintain consistent performance and prevent thermal degradation.

Proper lubrication and friction management are crucial for the reliable operation of belt tensioners. Lubricants or bearing configurations are employed to minimize friction, reduce wear, and prevent premature failure. Adequate lubrication and friction management contribute to the consistent operation and longevity of the tensioner, ensuring optimal belt tension over time.

Regular maintenance and inspection are essential for ensuring the reliability and durability of belt tensioners. Periodic checks for signs of wear, proper alignment, and tension adjustment are necessary to identify potential issues and take corrective measures. Following the manufacturer’s recommended maintenance schedule and procedures helps prolong the life of the tensioner and maintain consistent belt tension.

In summary, the reliability and durability of belt tensioners are crucial for ensuring consistent belt tension in belt-driven systems. The design and construction of tensioners, their load capacity, resistance to wear and fatigue, corrosion and contamination resistance, temperature stability, lubrication and friction management, as well as regular maintenance and inspection, all contribute to their ability to maintain optimal belt tension over time. By selecting high-quality tensioners and following proper maintenance practices, consistent belt tension can be achieved, leading to reliable and efficient operation of belt-driven systems.

Can you explain the principles behind belt tensioner operation and adjustment?

Belt tensioners operate based on a set of principles aimed at maintaining the proper tension in belts. They are designed to apply and control the tension in the belt drive system, ensuring optimal performance and longevity. Here’s a detailed explanation of the principles behind belt tensioner operation and adjustment:

- Tensioning Mechanism:

- Proper Tension Range:

- Belt Deflection:

- Adjustment and Maintenance:

- Monitoring and Inspection:

- Consideration of Environmental Factors:

Belt tensioners typically consist of a mechanical mechanism that applies force to the belt, adjusting its tension. The tensioning mechanism can vary depending on the specific design and application. Common types of tensioners include spring-loaded tensioners, hydraulic tensioners, and automatic tensioners. These mechanisms are designed to exert a specific amount of force on the belt, maintaining the desired tension level.

Each belt has a specific tension range recommended by the manufacturer. This range ensures optimal power transmission, minimal slippage, and reduced wear. Belt tensioners are adjusted to operate within this recommended tension range. It is important to follow the manufacturer’s guidelines or specifications to determine the appropriate tension for a specific belt and application.

During operation, belts experience a certain degree of deflection or sag between the pulleys. Belt tensioners account for this deflection and compensate for it by applying the appropriate tension. The tensioner mechanism is adjusted to ensure that the belt maintains the desired tension even when subjected to deflection. This helps to prevent excessive slack or tightness in the belt, optimizing power transmission and minimizing wear.

Belt tensioners require periodic adjustment and maintenance to ensure optimal performance. The adjustment process involves inspecting the belt tension, evaluating its deflection, and making necessary adjustments to bring it within the recommended tension range. Tensioners may feature adjustment bolts, nuts, or other mechanisms that allow for precise tension adjustments. It is essential to follow the manufacturer’s instructions and use appropriate tools to adjust the tensioner correctly.

Regular monitoring and inspection of belt tensioners are crucial for their effective operation. This involves visually examining the tensioner for signs of wear, damage, or misalignment. It is also important to check the belt tension regularly using appropriate tension measuring tools or techniques. By monitoring the tensioner and the belt’s condition, any issues can be identified and addressed promptly, ensuring optimal tension and preventing potential problems.

Environmental factors such as temperature, humidity, and operating conditions can influence belt tension. Belt tensioners should be adjusted and maintained considering these factors. For example, temperature changes can cause the belt to expand or contract, affecting its tension. Tensioners may incorporate features to compensate for such variations, ensuring consistent tension under different environmental conditions.

In summary, belt tensioner operation and adjustment are based on principles that involve applying the appropriate tension to the belt, accounting for deflection, operating within the recommended tension range, and considering environmental factors. Tensioners are adjusted and maintained to ensure optimal power transmission, minimize wear, and prevent issues such as slippage or excessive tension. Regular monitoring and inspection of tensioners and belts are essential for their reliable operation and longevity.

What industries and machinery commonly use belt tensioners for optimal belt performance?

Various industries and machinery rely on belt tensioners to achieve optimal belt performance. Here’s a detailed explanation of the industries and machinery that commonly use belt tensioners:

- Automotive Industry:

- Industrial Machinery:

- Power Generation:

- Agricultural Equipment:

- Construction and Mining:

- HVAC and Refrigeration:

The automotive industry extensively utilizes belt tensioners in vehicles for various applications. Belt tensioners are commonly found in the engine accessory drive system, where they maintain the proper tension in the serpentine or V-belts that power components such as the alternator, air conditioning compressor, power steering pump, and water pump. Belt tensioners ensure efficient power transmission, reduce belt slippage, and contribute to the overall reliability and performance of automotive engines.

A wide range of industrial machinery relies on belt tensioners for optimal belt performance. Industries such as manufacturing, food processing, packaging, printing, and material handling use belt-driven systems for conveyor belts, production lines, pumps, compressors, and other equipment. Belt tensioners help maintain the proper tension in these applications, ensuring smooth operation, efficient power transmission, and minimizing downtime due to belt slippage or failure.

In the power generation sector, belt tensioners are commonly used in applications such as generators, turbines, and auxiliary equipment. These systems often utilize belts to transfer power between components, and the tensioners play a crucial role in maintaining proper belt tension. Belt tensioners help optimize power transmission efficiency, reduce vibrations, and enhance the overall reliability of the power generation equipment.

Agricultural machinery, including tractors, combines, and other farming equipment, often rely on belt-driven systems for various operations. Belt tensioners are utilized to maintain the tension in belts powering agricultural implements, such as harvesters, balers, and grain conveyors. By ensuring optimal tension, belt tensioners contribute to the efficient operation of agricultural equipment, improving productivity and reducing maintenance requirements.

Construction and mining industries commonly employ belt-driven systems in equipment such as excavators, loaders, crushers, and conveyor systems. Belt tensioners are used to maintain the proper tension in belts powering these machines, ensuring reliable and efficient operation in demanding environments. Belt tensioners help prevent belt slippage, reduce downtime, and contribute to the longevity of the equipment.

The HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industries rely on belt-driven systems for various applications, including fans, blowers, compressors, and pumps. Belt tensioners are critical in maintaining the proper tension in these systems, ensuring efficient power transmission and reducing belt-related issues such as slippage or premature wear. Belt tensioners contribute to the overall performance and reliability of HVAC and refrigeration equipment.

In addition to the industries mentioned above, belt tensioners are also utilized in a wide range of other machinery and equipment, including woodworking machinery, textile machinery, marine propulsion systems, and more. The versatility and benefits of belt tensioners make them a valuable component for achieving optimal belt performance in numerous industrial and mechanical applications.

editor by CX 2024-04-15

China Hot selling CZPT Isle 6L Qsl9 Truck Engine V Belt Tensioner 3974102 for Truck and Excavator axle alignment

Product Description

Xihu (West Lake) Dis.feng ISLE 6L QSL9 truck engine v belt tensioner 3974102 For Truck and excavator

Our Main products : cylinder block,cylinder head,crankshaft,camshaft,connecting rod,connecting rod bearing,valve,plunger,nozzle,exhaust valve,engine assy,feed pump,fan blade,gasket kit,glow plug/engine preheater,intake valve,liner,liner kit/rebuild kit,main bearing/crankshaft bearing,nozzle,nozzle piping,oil pump,piston,piston pin,piston ring,plunger,seat ,thrust bearing,valve guide,valve seat,valve seal,gasket full set ,water pump , turbocharger,genarator, starter,sensor…

| USE FOR | EXCAVATOR/ Truck |

| MACHINE MODEL | QSL9 |

| PART NUMBER | 3974102 |

| BRAND | Cummins |

Why choose our company?

——Company information

HangZhou Marun Machinery Equipment Co., Ltd is located in HangZhou China,Our company

established in 2008, it’s parent company -HangZhou Qipeng Machinery Equipment Co,.Ltd. We are authorized agent of Isuz,Yanmar and Mahle in China, agent of Isuz since it founded in 1990 ,specialized in excavator engine spare parts ,engine assembly and construction machinery for 30 years.

About ISUZ :

As a largest, most varieties and professional,leading ISUZ agent in China, we offer a full range of genuine ISUZ engine accessories and complete engine.The business scope are as follows:

Engine model:4JB1,C240,4BD1,4LE1,4LE2,4JG1,4JG2,4BD1,4BG1,4HK1,6HK1,6BD1,6BG1,6SD1,6RB1,6UZ1,6WG1.

Besides , we also can supply parts for machines like SUMITOMO,CASE,KOBELCO ,MITSUBISHI,CUMMINS ,KAWASAKI and so on

About CZPT :

As we all knows,if there were only two cars in the world, then one must use MAHLE spare parts.It’s products range cover construction machinery engine parts and auto engine parts,parts including:piston/cylinder/liner kit/valves/bearings/gasket kit/piston ring/filter .Apply to ISUZ,KOBELCO,CATER,KOMATS,CUMMINS,MITSUBISHI,HINO,DEUTZ and so on .

——Company Advantages

1. We have profession knowledge about engine parts ,more than 20 years experience in engine parts.

2. We can offer new and used genuine parts, oem, good quality made in china parts to you.

3. The genuine parts will give weight,price when quotation.

4. Genuine stock pictures will send if you need .

5.All parts can check with part number,all parts can order follow part number.

6. Quick delivery time,will delivery the goods within 3 days.

7. Safe packing to protect the goods, such as wooden box, Iron sheet for our parts.

8. Small quantity can accept.

——FAQ:

Q1:How long is the warranted time?

For natural broken, 3 months. Guarantee genuine parts.

Q2: What’s payment you can accept?

T/T, WESTERN UNION, CHINESE BANK,

Q3: What’s package? Can you give me the package according my requirement?

Yes, Original packing or Neutral packing with wooden box or carton

Q4: How about the lead time?

1) Stock available: 1-3days.

2) Out of stock: It’s according to your quantity, and we have cooperated with factory.

We will let you know when we quote.

Q5: What’s the shipping way you can offer?

1) Big order: By sea or by air.(It can reduce the costs)

2) Small order: DHL, TNT, UPS, FEDEX, EMS,

Q6: Whta’s the terms of the transaction?

EXW, FCA, FAS, FOB, C&F, CIF, CPT, CIP, DAF, DES,DDP.

Q7: Do you accept small order?

Yes, small order can accept.

Q8: What’s brand you can offer in your company?

1) OEM, 100% GENUINE PARTS, COPY(Made in China)

2) GENUINE PARTS.

We are seeking the chances to meet all the friends both from at home and abroad for the CZPT cooperation.

We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

,

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Engine Part |

|---|---|

| Application: | Excavator |

| Certification: | Standard |

| Condition: | New |

| Machine Model: | Qsl9 |

| Stock Status: | Available |

| Customization: |

Available

| Customized Request |

|---|

Can you describe the various mounting options and installations for belt tensioners in different settings?

Mounting options and installations for belt tensioners can vary depending on the specific application and the belt-driven system’s design. Different settings may require different approaches to ensure proper alignment, tensioning, and functionality of the tensioner. Here’s a detailed description of the various mounting options and installations for belt tensioners in different settings:

- Fixed Mounting:

- Adjustable Mounting:

- Spring-Loaded Tensioners:

- Idler Pulley Tensioners:

- Hydraulic Tensioners:

- Overhead Tensioners:

- Combination Mounting:

The most common mounting option for belt tensioners is fixed mounting. In this configuration, the tensioner is rigidly attached to a stationary part of the system, such as the engine block or a structural component. Fixed mounting provides stability and ensures that the tensioner remains in a fixed position relative to the belt. It is widely used in automotive, industrial, and machinery applications.

In some applications, adjustable mounting options are preferred to accommodate variations in belt length, alignment, or tension requirements. Adjustable tensioners allow for fine-tuning of the tensioning force by enabling adjustments in the tensioner’s position. This can be achieved through slots, elongated holes, or adjustable brackets that provide flexibility in the tensioner’s placement. Adjustable mounting is beneficial when precise tension adjustment is necessary or when belt drives undergo frequent changes.

Spring-loaded tensioners are commonly used in belt-driven systems. These tensioners incorporate a spring mechanism that applies constant tension to the belt. Spring-loaded tensioners can be mounted in various configurations, including fixed or adjustable mounting. The spring mechanism compensates for belt elongation, wear, or thermal expansion, ensuring consistent tension throughout the belt’s operational life.

Idler pulley tensioners utilize an additional pulley to redirect the belt’s path and apply tension. The tensioner is typically mounted on an adjustable bracket or arm, allowing for precise positioning of the idler pulley relative to the belt. Idler pulley tensioners are often used in serpentine belt systems, where multiple accessories are driven by a single belt. Proper alignment and tensioning of the idler pulley are crucial for efficient power transmission and belt longevity.

Hydraulic tensioners employ a hydraulic cylinder or piston to apply tension to the belt. These tensioners are commonly used in applications where high tension forces or dynamic tension control is required. Hydraulic tensioners may have specific mounting requirements due to the need for hydraulic connections, such as hoses or fittings. They are often used in heavy-duty machinery, automotive engines, or other systems demanding precise tension control.

In certain settings, such as conveyor systems or overhead power transmission systems, belt tensioners may be mounted overhead. Overhead tensioners are typically suspended from a support structure, allowing the tensioner to apply tension to the belt from above. This configuration helps maximize space utilization and facilitates maintenance and belt replacement in vertically-oriented systems.

In complex belt-driven systems, a combination of mounting options may be employed. For example, a fixed tensioner may be used in one location, while an adjustable tensioner is used in another to accommodate different belt lengths or alignment requirements. Combination mounting allows for customized tensioning solutions tailored to the specific system design and operational needs.

It is important to note that the specific mounting option and installation for a belt tensioner will depend on the system’s design, space constraints, belt type, and the manufacturer’s recommendations. It is essential to follow the manufacturer’s guidelines and specifications for proper tensioner installation to ensure optimal performance and longevity of the belt-driven system.

In summary, the mounting options and installations for belt tensioners can include fixed mounting, adjustable mounting, spring-loaded tensioners, idler pulley tensioners, hydraulic tensioners, overhead tensioners, and combinations thereof. Each mounting option offers advantages and considerations depending on the application’s requirements and the specific belt-driven system’s design.

What are the typical signs of improper belt tension, and how can belt tensioners address these issues?

Improper belt tension can lead to various issues in belt-driven systems. Recognizing the signs of improper tension is crucial for identifying and addressing potential problems. Belt tensioners play a crucial role in addressing these issues by adjusting and maintaining the proper tension in the belts. Here’s a detailed explanation of the typical signs of improper belt tension and how belt tensioners can address these issues:

- Slippage:

- Excessive Wear:

- Noise and Vibration:

- Overheating:

- Premature Belt Failure:

- Reduced Power Transmission Efficiency:

Slippage occurs when the belt slips on the pulleys instead of maintaining a firm grip. It can be caused by insufficient tension. Signs of slippage include a noticeable decrease in power transmission efficiency, a burning smell from friction, or visible wear on the belt and pulleys. Belt tensioners address slippage by applying the necessary force to increase the tension, improving the grip between the belt and the pulleys and minimizing slippage.

Improper tension can cause excessive wear on belts, pulleys, and other components. Insufficient tension may lead to belt slipping, resulting in accelerated wear. On the other hand, excessive tension can cause excessive stress and strain on the belt, leading to premature wear and potential damage. Belt tensioners help address excessive wear by adjusting the tension to the manufacturer’s recommended range, ensuring proper belt engagement and minimizing wear on the belt and associated components.

Improper belt tension can contribute to increased noise and vibration levels in the system. Insufficient tension may cause belt flapping or fluttering, leading to vibrations and noise. Excessive tension can create excessive forces and induce resonance, resulting in vibrations and noise as well. Belt tensioners address these issues by maintaining the correct tension, minimizing belt movement, reducing vibrations, and lowering noise levels, resulting in smoother and quieter operation.

Inadequate belt tension can cause overheating due to increased friction between the belt and the pulleys. Overheating may manifest as excessive heat radiating from the belt or pulleys, discoloration of the belt, or even belt degradation. Belt tensioners help address overheating by maintaining the proper tension, ensuring efficient power transmission and minimizing friction, which in turn reduces heat generation and helps prevent overheating issues.

Improper tension significantly increases the risk of premature belt failure. Insufficient tension can lead to belt slippage, accelerated wear, and reduced belt lifespan. Excessive tension can cause excessive stress and fatigue, leading to belt breakage or premature damage. Belt tensioners address these issues by maintaining the correct tension, distributing the load evenly across the belt, minimizing stress, and promoting longer belt life.

Improper belt tension can result in reduced power transmission efficiency. Insufficient tension leads to belt slipping, reducing the amount of power transferred from the driving pulley to the driven pulley. Excessive tension can cause increased friction and energy losses. Belt tensioners address these issues by ensuring the proper tension, maximizing the grip between the belt and the pulleys, and optimizing power transmission efficiency.

In summary, improper belt tension can manifest through signs such as slippage, excessive wear, noise and vibration, overheating, premature belt failure, and reduced power transmission efficiency. Belt tensioners address these issues by adjusting the tension to the recommended range, minimizing slippage, reducing wear, damping vibrations, preventing overheating, promoting longer belt life, and optimizing power transmission efficiency. Regular inspection and adjustment of belt tension using appropriate tensioners are essential for maintaining optimal belt performance and preventing potential issues.

Can you describe the various types of belt tensioners, such as automatic or manual tensioners?

There are various types of belt tensioners available, each designed to fulfill specific requirements in maintaining belt tension. Here’s a description of the different types of belt tensioners:

- Manual Belt Tensioners:

- Automatic Belt Tensioners:

- Hydraulic Belt Tensioners:

- Eccentric Belt Tensioners:

- Idler Pulley Tensioners:

Manual belt tensioners are the most basic type and require manual adjustment to set and maintain the desired tension. They typically consist of an adjustable arm or bracket that can be moved to increase or decrease the tension in the belt. Manual tensioners are commonly used in applications where tension adjustments are infrequent or can be easily accessed for manual adjustment. They are simple, cost-effective, and widely used in various industries.

Automatic belt tensioners, also known as self-adjusting or spring-loaded tensioners, are designed to maintain the proper tension automatically. They incorporate a spring mechanism that applies constant tension to the belt, compensating for belt elongation and wear over time. Automatic tensioners are commonly used in applications where frequent manual adjustments are impractical or where consistent tension control is essential. They provide convenience, minimize maintenance requirements, and ensure optimal tension without the need for manual intervention.

Hydraulic belt tensioners utilize hydraulic pressure to maintain belt tension. They consist of a hydraulic cylinder or piston that applies force to the tensioner arm, adjusting the tension in the belt. Hydraulic tensioners are commonly used in applications with high load requirements or variable operating conditions. They provide precise tension control, can compensate for changes in temperature and load, and are often employed in heavy-duty industrial machinery and automotive applications.

Eccentric belt tensioners use an eccentric mechanism to adjust the tension in the belt. They typically feature an eccentric pulley or roller that can be rotated to increase or decrease the tension. Eccentric tensioners are commonly used in applications where precise tension adjustments are required, such as high-performance engines or systems with specific belt tension specifications. They offer fine-tuning capabilities and are often found in automotive racing, performance tuning, and specialized machinery.

Idler pulley tensioners, also known as fixed tensioners or idler pulley assemblies, are a type of belt tensioner that utilizes an idler pulley to maintain tension. They are typically positioned on the slack side of the belt, providing guidance and tension control. Idler pulley tensioners are commonly used in applications where a fixed tension is desired, and the tensioning capability is provided by other components in the system, such as an automatic tensioner or an adjustable drive pulley.

In addition to these types, there are also specialized belt tensioners designed for specific applications or industries, such as torsional vibration dampers used in automotive engines to reduce vibrations, or belt tensioners with built-in dampening mechanisms to minimize noise in certain applications.

Overall, the choice of belt tensioner depends on factors such as the application requirements, load conditions, frequency of tension adjustments, and the desired level of automation and control. Selecting the appropriate type of belt tensioner is crucial to maintaining optimal belt tension and ensuring the efficient and reliable operation of belt-driven systems.

editor by CX 2024-03-15

China best Automotive V Belt Manufactures New V Belt Tensioner Auto V Belt Size near me factory

Product Description

Product Description:

The top and the bottom are encased by the weapper, Both sides are rubber . V belt of tooth shape groove is designed for the bottom to improve the tlexral property.

| No. | Name | Function | Material |

| 1 | Top Fabric | Protect the CZPT tensile member | Polyester Cotton Canvas |

| 2 | Core Cord | Nuclear material to pass the dynamicTop Fabric force | Polyester |

| 3 | Bottom Rubber | Side compression resistant and section | CR,EPDM |

| 4 | Bottom Fabric | Absorb the impact and prevent crack of the core rubber | Elastic Fabric |

| Section Size of lndustrial Raw Edge V Belts |

| Type | Top width (mm) | Belt Thickness (mm) | Angle(°) |

| HM | 10.5 | 8.0 | 38 |

| AX | 13 | 8.0 | 38 |

| BX | 17 | 11 | 38 |

| CX | 22 | 14 | 38 |

| DX | 32 | 19 | 38 |

| EX | 38 | 23 | 38 |

| Section Size of Raw Edge Narrow Belts |

| Type | Top width | Belt Thickness | Angle |

| XPZ | 9.7 | 8.0 | 40 |

| XPA | 12.7 | 10 | 40 |

| XPB | 16.3 | 13 | 40 |

| XPC | 22 | 18 | 40 |

| 9NX | 9.5 | 8 | 40 |

| 15NX | 16 | 13.5 | 40 |

| 25NX | 25.4 | 23 | 40 |

| Section Size of Raw Edge V Belts for Automobile |

| Type | Top width | Wrapped V belt | Raw edge V belt | REF | REC | Angle |

| AV-10/9.5 | 10.0 | 8.0 | 7.5 | 7.5 | 8.0 | 40 |

| AV-13/12.5 | 13.0 | 10.0 | 8.5 | 8.5 | 9.0 | 40 |

| AV-15 | 15.0 | 9.0 | – | – | – | 40 |

| AV-17 | 16.5 | 10.5 | 9.5 | 9.5 | 11.0 | 40 |

| AV-22 | 22.0 | 14.0 | – | – | 13.0 | 40 |

Company introduction:

The First:HangZhou Grand AUTO PARTS CO.,LTD.is a professional auto parts corporation with operations including development,productnumber of high-tech production bases in mainland China.

The Second:We have established partnerships with big purchasers and the renowned brands in France and Egypt and Iraq to carry out the OEM.

The Third:The products are sold into over 50 countries around the world with Europe, America,the middle east and the southeastAsia and Africa as the main destinations.

What to Look for in a Belt Tensioner

If you notice the power steering, air conditioning, or power steering stops working, chances are that your belt tensioner has been compromised. A compromised belt tensioner can be completely destroyed overnight, or it can last for a long time before it breaks. Either way, you should never drive with a faulty belt tensioner. It’s far better to have it replaced before the engine shuts down completely. In addition, replacing a belt tensioner will prevent other complications, such as power steering or air conditioning, from occurring.

Misaligned idler pulley

If the tensioner arm is not rotating freely or has an abnormal chirping noise, it could be the result of a misaligned idler pulley. If this is the case, replace the idler. If the idler does not move, you may need to adjust the accessory mount points or use a laser alignment tool. The tensioner arm is only 1 part of the tensioner.

A misaligned idler pulley on a belt tensioner is usually the cause of a squeaking noise. If this noise continues even after a replacement of the belt, it’s time to replace the whole belt. A misaligned idler pulley can also be the cause of premature belt wear. If the idler pulley is out of alignment, it could also cause the belt to wear too fast and lead to the premature failure of the timing belt.

The tensioner pulley is made of nylon, steel, or plastic. It may be flat or grooved. Before replacing it, check for any cracks, dents, or debris on the pulley’s surface. Plastic pulleys may have broken sidewalls. If the idler pulley is worn out, you might also notice squealing noises when the vehicle is in motion.

The misalignment of a belt is most pronounced when the span between the 2 pulleys is short. When the span is long, however, diagnosing the problem becomes more complicated. Small degrees of offset may not be visible to the naked eye, but a laser alignment tool can help identify these subtle variations. In order to identify a misaligned idler pulley on a belt tensioner, you must first determine its cause.

When the tensioner’s idler pulleys are out of line, a belt tensioner will not be able to properly adjust the torque that the belt is under. This may result in squealing noises. If this is the case, it is time to call a mechanic. He or she will be able to determine the cause and correct it. If you suspect the problem, your next step is to replace the idler pulley on the belt tensioner.

If the ribbed belt is not properly aligned, you may have a misaligned idler pulley. To fix the misalignment, locate the belt adjustment bolt underneath the hood. You should be careful not to damage the alternator or battery terminal while doing this task. If you do accidentally connect the battery positive to the earth, you might be able to damage the ribbed belt and ruin your vehicle’s timing.

Besides a misaligned idler pulley on the belt tensioner, another problem may be the alternator’s serpentine belt. If your car’s alternator belt is not aligned properly, you could have misaligned the alternator’s pulley or a worn-out bearing. Regardless of the cause of your problem, you should have the belt inspected.

Bad idler pulley

Having a Bad Idler Pulley on a Belt Tensioner? If this sounds familiar, then it’s probably time to change it. Idler pulleys slowly take hits while the engine is running, causing the belt to wrap and bend. Eventually, the belt will slip, and a new idler pulley should be installed to ensure optimal tension. But before you spend a dime on a new one, let’s talk about what to look for.

Symptoms of a Bad Idler Pulley: If the noise persists, there is a problem with the idler pulley or its bearing. These parts wear out over time and may eventually cause a cracked idler pulley or serpentine belt. Not only will the idler pulley create an irritating noise, but it will also damage the belt itself, leading to overheating, stalled engine, and even damage the head gaskets. Thankfully, a Bad Idler Pulley on a Belt Tensioner is easily replaced and will only cost about $40.

Although the Idler Pulley is not the most popular component on a car, it’s a critical part that ensures that the engine runs smoothly. It’s easy to overlook this part, but its failure can make it impossible for your vehicle to operate at its optimal level. Moreover, a Bad Idler Pulley on a Belt Tensioner will cause your engine to malfunction, so it’s essential that you check it at regular intervals.

If you notice a squealing noise while driving, the Idler Pulley is likely the culprit. Because of friction between the engine belt and idler pulley, the engine belt rubs against the pulley, causing it to squeak and make a clicking noise. This squealing noise will continue until the problem is repaired or replaced. It’s time to start addressing the problem before it becomes too late.

If you notice the tensioner pulley moving away from the engine, it’s most likely that the pulley is malfunctioning. A belt that is loose or slack may make it difficult to start the car, or your engine may even overheat. If this occurs, it’s crucial to replace the Idler Pulley as soon as possible, because a Bad Idler Pulley on a Belt Tensioner can seriously damage your vehicle.

The Idler Pulley facilitates the motion of the engine belt. It serves as a smooth rotating point that allows the belt to loop without a barrier. Over time, this part of the system will begin to show signs of wear and tear, and replacement is vital to protect your engine, serpentine belt, and other accessories. An early warning sign of a problem is a squealing sound coming from the engine area.

Broken tensioner arm

The belt tensioner is a piece of machinery that is used to keep the belt tight. If this part breaks, you can easily repair it yourself using a long-handled ratchet, serpentine belt tool, or a socket. To repair the tensioner, simply remove the drive belt from the pulley and rotate it to release tension. Check for roughness, resistance, or binding of the drive belt.

Noises caused by the tensioner are a sign of a damaged component or excessive oscillation. These noises are usually caused by worn internal components or the tensioner’s pivot bushing. In some cases, the vibration damping system or a worn-out alternator pulley could also be to blame. If this is the case, replace the pulley and tensioner together. To check the condition of your belt tensioner, follow these steps.

In addition to worn-out springs, a loose or broken pivot arm could be causing your belt to misalign. A worn-out tensioner pulley bushing will also cause vibrations, noise, and seizing. Lastly, a broken tensioner spring could be preventing the belt from maintaining proper tension. Broken springs are also prone to loss of tension due to heat. Damaged tensioner housing can also affect belt tension.

Once the belt is installed, you need to check the condition of the pulley and the tensioner arm. Make sure that the pulley is moving and that the arm is moving smoothly with the cranking and releasing. If the arm is wobbling, the tensioner is failing. If the pulley wobbles or excessive chattering occurs, the tensioner is failing. It can also be seized or jammed.

If the tensioner arm has broken, replace it. Replacing the tensioner can be a tedious task. Be sure to use a suitable tool to tighten the pulley and tensioner. If you are not sure of how to replace the pulley, try using a serp belt tool. Another good option is to purchase a 3/8 drive ratchet. If you don’t have this tool, you can use a long 3/8 extension and a deep socket.

The belt tensioner assembly can fall off the engine, causing damage to the timing belt. If you are replacing it, you must replace it with a new one, and tighten all of the mounting bolts before reinstalling it. To avoid further damage to the engine, ensure you replace the belt with a new tensioner and a new belt. The tensioner is bolted to the engine’s timing cover, so make sure you carefully tighten the bolts when replacing it.

China Hot selling Polyurethane V Belt New V Belt Tensioner V Belt Supplier with Good quality

Product Description

Product Description:

The top and the bottom are encased by the weapper, Both sides are rubber . V belt of tooth shape groove is designed for the bottom to improve the tlexral property.

| No. | Name | Function | Material |

| 1 | Top Fabric | Protect the CZPT tensile member | Polyester Cotton Canvas |

| 2 | Core Cord | Nuclear material to pass the dynamicTop Fabric force | Polyester |

| 3 | Bottom Rubber | Side compression resistant and section | CR,EPDM |

| 4 | Bottom Fabric | Absorb the impact and prevent crack of the core rubber | Elastic Fabric |

| Section Size of lndustrial Raw Edge V Belts |

| Type | Top width (mm) | Belt Thickness (mm) | Angle(°) |

| HM | 10.5 | 8.0 | 38 |

| AX | 13 | 8.0 | 38 |

| BX | 17 | 11 | 38 |

| CX | 22 | 14 | 38 |

| DX | 32 | 19 | 38 |

| EX | 38 | 23 | 38 |

| Section Size of Raw Edge Narrow Belts |

| Type | Top width | Belt Thickness | Angle |

| XPZ | 9.7 | 8.0 | 40 |

| XPA | 12.7 | 10 | 40 |

| XPB | 16.3 | 13 | 40 |

| XPC | 22 | 18 | 40 |

| 9NX | 9.5 | 8 | 40 |

| 15NX | 16 | 13.5 | 40 |

| 25NX | 25.4 | 23 | 40 |

| Section Size of Raw Edge V Belts for Automobile |

| Type | Top width | Wrapped V belt | Raw edge V belt | REF | REC | Angle |

| AV-10/9.5 | 10.0 | 8.0 | 7.5 | 7.5 | 8.0 | 40 |

| AV-13/12.5 | 13.0 | 10.0 | 8.5 | 8.5 | 9.0 | 40 |

| AV-15 | 15.0 | 9.0 | – | – | – | 40 |

| AV-17 | 16.5 | 10.5 | 9.5 | 9.5 | 11.0 | 40 |

| AV-22 | 22.0 | 14.0 | – | – | 13.0 | 40 |

Company introduction:

The First:HangZhou Grand AUTO PARTS CO.,LTD.is a professional auto parts corporation with operations including development,productnumber of high-tech production bases in mainland China.

The Second:We have established partnerships with big purchasers and the renowned brands in France and Egypt and Iraq to carry out the OEM.

The Third:The products are sold into over 50 countries around the world with Europe, America,the middle east and the southeastAsia and Africa as the main destinations.

How to Prevent Timing Belt Problems

Unlike their predecessors, timing chains and timing belts are made of rubber and synchronize the opening and closing of valves in the engine. While their benefits are numerous, they are prone to wear and tear over time. Here are some tips for ensuring your timing belt lasts for many years. Listed below are some of the most common problems that you may encounter when changing your timing belt. Read on to find out how to prevent them and keep your car running at peak performance.

Timing belts are rubber

There are many advantages to using timing belts in your car. They are lightweight and reduce the strain on your vehicle’s internal components. They are also quiet when running, so you won’t have to listen to your car to know that maintenance is needed. If you’re concerned about noise, a quiet engine can help you determine whether your timing belts are broken or if you need to replace them altogether. A quiet engine can also help you notice signs of wear and tear before you do.

Regardless of material, rubber timing belts can be susceptible to stretching and breaking. They also are susceptible to high temperatures and the lubrication of motor oil, reducing their lifespan. Manufacturers have responded to this problem by creating timing belts made of engine-temperature-resistant rubber materials. The improved rubber compounds also provide greater strength and resistance to distortion. Reinforcing fibers also protect the teeth from shearing, reducing the risk of a worn-out timing belt.

While the open-ended, or spliced, types of timing belts have many advantages, they are generally unsuitable for high-speed applications. In most cases, rubber timing belts are used in high-speed machine tools and automatic doors. They are also quiet and require minimal maintenance. These characteristics make rubber timing belts a great choice for high-speed applications. You can even order custom-made timing belts for unusual applications.

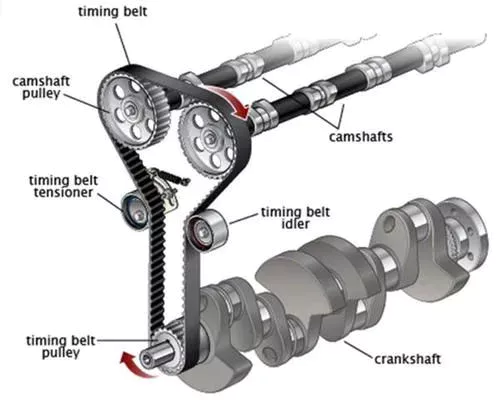

Timing belts are important for the functioning of an engine. They link the camshaft and crankshaft to the crankshaft. They control the movement of valves and pistons. If a timing belt fails, it can cause major damage to the engine. If you are unsure of the benefits of rubber timing belts, consider a video on the topic. This will provide you with more information on timing belts.

They synchronize the opening and closing of the engine’s valves

During the combustion process of the engine, the valves in the cylinder head open and close. Fresh air enters the cylinder, which burns with the fuel to generate power. Exhaust escapes the engine through the exhaust valve. Each cylinder contains between 2 and 4 valves. The timing belt drives a camshaft, which rotates in a precise manner to synchronize the valve opening and closing.

A timing belt is a toothed rubber belt that connects the engine’s crankshaft to the crankshaft. Like most rubber parts, timing belts degrade over time, so it’s important to replace them at the proper intervals. Replacement intervals vary depending on the make and model of the vehicle, but they should be replaced every 60 to 90 thousand miles.

A broken timing belt will not start the engine. A timing belt driven vehicle will need to be towed to a repair shop for repairs. In the automotive industry, timing belts drive both “free running” and “interference” engines. The timing belt transfers the crankshaft’s rotation to the camshafts, which in turn actuate the valves in the intake and exhaust system. When they malfunction, the pistons can contact open valves, bending or punching them.

Timing belts also work with pistons and connecting rods to create power. Perfect timing is essential for the engine to run smoothly. The timing belt regulates both the pistons and the valves. If they are out of sync, they may not ignite properly, leading to catastrophic engine failure. When you’re looking for a replacement, look for these signs of wear.

They are lighter, quieter and more efficient than timing chains

While the initial choice was for quieter performance, variable timing has led to greater efficiency and power. While noise is a factor, the average consumer cannot tell the difference. And while timing belts are generally lighter and quieter, a chain can be more noisy than a belt, which can cause more engine damage. If you’re unsure whether you should opt for a chain or a belt, consult your owner’s manual.

A timing chain functions similar to a timing belt but is made from metal and is housed inside the engine compartment. It receives its lubrication from engine oil. Timing chains can last a long time as long as you keep them properly maintained. A timing chain is not as efficient as a timing belt, but it is more accurate, quieter and easier to maintain.

A timing belt uses teeth to time the movement of various components in an engine. When the timing belt is broken, the valves in the engine will not be in sync, leading to a loss of pressure in the combustion chamber. This can cause a plethora of engine problems and cost-increasing repairs. A timing belt is also quieter and requires less lubrication, so it is safer and quieter than a timing chain.

After the advent of variable valve timing, cars began to use a timing chain. This design improved engine performance and reduced maintenance, but it also caused a backlash as consumers were no longer interested in this kind of routine maintenance. Today, however, timing chains are making a comeback in the automotive industry. While modern chains can still be noisy, they are easier to maintain, are lighter, and last longer than their chain counterparts.

They wear out over time

Even the best drive belts will eventually wear out. The main causes of belt wear include mileage and heat. The belt bends as it passes the pulley, producing heat that hardens the rubber. When the belt slips, it increases friction, accelerating the process. A worn-out belt can be very difficult to start, causing an engine to lose fuel efficiency. To help prevent this problem, check the belt for wear and tear.

A timing belt is an engine component that connects the camshaft to the crankshaft and controls the timing of combustion. These belts are made of industrial-strength rubber, and often contain nylon-reinforced cords. Although they are meant to last, they will eventually wear out. If the timing belt fails, your engine won’t run smoothly or you could spend thousands of dollars fixing it.

A faulty timing belt can cause the valves to open too early or too late, causing poor combustion and a drop in engine performance. If the timing belt breaks, the valves may hit the pistons and cause damage. This can lead to engine breakage, which requires a new engine. To prevent this, you should replace the timing belt every couple of thousand miles. If you can’t find a reliable mechanic, it is best to seek professional help from a reputable mechanic.

Another warning sign that your timing belt needs replacing is a ticking sound coming from within your engine. This is an indication of a lower oil pressure than normal. Low oil pressure can affect the timing belt as it can cause the tensioner that holds the belt taut will lose pressure. Eventually, the belt may even break, allowing the camshafts to slip and break. Once this happens, it is time to replace the timing belt.

They can be repaired

Timing belts can be repaired. If your timing belt breaks, you can take your car to a repair shop to have it repaired or replaced. The price of a repair depends on the labor hours and how many hours it takes to do the job. A bad timing belt can ruin your engine and cause it to break down completely. If you’re unable to drive your vehicle, it may require towing and a new engine.

For most drivers, a timing belt replacement will cost about $1,000 at a dealership. Luckily, you can often get the same service for less at an independent auto repair shop. Often, a timing belt repair requires replacing the water pump, too. It makes sense to replace both at the same time. But remember that timing belts are more complicated than that. If you’re worried about the cost, you can replace the water pump along with the timing belt.

If you’re in the mood to do this repair, there are many companies that offer this service. The cost is relatively low and you’ll probably save hundreds of dollars over the course of the job. However, timing belt repair is not a simple job and must be done correctly or you could end up damaging your car engine. Therefore, it’s important to know how to repair a timing belt yourself to avoid the high price of hiring a mechanic.

When timing belts start to fail, there are a few warning signs you can listen for. A difficult start-up can be a sign that your belt needs to be replaced. Also, thick smoke coming from the tailpipe can be a sign that the timing belt needs to be changed. In addition to these symptoms, your timing belt may have a crack or broken gear teeth, which means it needs to be replaced.

China supplier Rubber V Belt Tensioner Engine Rubber Fan Drive V Belt Supplier near me manufacturer

Product Description

Product Description:

The top and the bottom are encased by the weapper, Both sides are rubber . V belt of tooth shape groove is designed for the bottom to improve the tlexral property.

| No. | Name | Function | Material |

| 1 | Top Fabric | Protect the CZPT tensile member | Polyester Cotton Canvas |

| 2 | Core Cord | Nuclear material to pass the dynamicTop Fabric force | Polyester |

| 3 | Bottom Rubber | Side compression resistant and section | CR,EPDM |

| 4 | Bottom Fabric | Absorb the impact and prevent crack of the core rubber | Elastic Fabric |

| Section Size of lndustrial Raw Edge V Belts |

| Type | Top width (mm) | Belt Thickness (mm) | Angle(°) |

| HM | 10.5 | 8.0 | 38 |

| AX | 13 | 8.0 | 38 |

| BX | 17 | 11 | 38 |

| CX | 22 | 14 | 38 |

| DX | 32 | 19 | 38 |

| EX | 38 | 23 | 38 |

| Section Size of Raw Edge Narrow Belts |

| Type | Top width | Belt Thickness | Angle |

| XPZ | 9.7 | 8.0 | 40 |

| XPA | 12.7 | 10 | 40 |

| XPB | 16.3 | 13 | 40 |

| XPC | 22 | 18 | 40 |

| 9NX | 9.5 | 8 | 40 |

| 15NX | 16 | 13.5 | 40 |

| 25NX | 25.4 | 23 | 40 |

| Section Size of Raw Edge V Belts for Automobile |

| Type | Top width | Wrapped V belt | Raw edge V belt | REF | REC | Angle |

| AV-10/9.5 | 10.0 | 8.0 | 7.5 | 7.5 | 8.0 | 40 |

| AV-13/12.5 | 13.0 | 10.0 | 8.5 | 8.5 | 9.0 | 40 |

| AV-15 | 15.0 | 9.0 | – | – | – | 40 |

| AV-17 | 16.5 | 10.5 | 9.5 | 9.5 | 11.0 | 40 |

| AV-22 | 22.0 | 14.0 | – | – | 13.0 | 40 |

Company introduction:

The First:HangZhou Grand AUTO PARTS CO.,LTD.is a professional auto parts corporation with operations including development,productnumber of high-tech production bases in mainland China.

The Second:We have established partnerships with big purchasers and the renowned brands in France and Egypt and Iraq to carry out the OEM.

The Third:The products are sold into over 50 countries around the world with Europe, America,the middle east and the southeastAsia and Africa as the main destinations.

Why Timing Belts Are So Important

What is a timing belt? A timing belt is a toothed synchronous belt that transfers rotary motion from the central motor to the drive pulley. Newer cars often have a synchronous timing belt to increase efficiency. Compared to traditional belts, these are quieter and more efficient. However, they do have their drawbacks. In this article, you’ll learn why timing belts are so important. And if you’re wondering how to replace them, keep reading to find out how you can do this quickly and affordably.

Timing belts are toothed, synchronous belts

Toothed, synchronous, and cogged belts are the 3 most common types of mechanical drive belts. Both toothed and synchronous belts are designed to run over pulleys with corresponding teeth. This positive engagement prevents slippage and speed loss. Timing belts can be toothed or toothless, and the toothed profile meshes with the grooves of the sprocket. They improve energy efficiency and reduce downtime. They are also smaller, quieter, and require no lubrication. These properties allow synchronous belts to operate at higher speeds than chains and gears.

These toothed belts are commonly used in motorcycles and automobiles. They are highly durable and can provide more power than friction-drive belts. Toothed belts are often designed for high-power transmissions and the primary drive of some motorcycles. While timing belts and synchronous belts may seem similar, they are quite different. Synchronous belts, or “toothed belts,” have 2 distinct failure modes. The former is gradual and preventive, whereas the latter is catastrophic.

Despite their similarities, timing belts are often not compatible with all machines. Excessive installation tension will result in belt tooth shear and stress breakage. The teeth of timing belts show signs of excessive tension, as illustrated in Figure 6. Broken teeth are caused by root cracks, which propagate along the tensile member. The individual teeth of the belt will separate from the body of the timing belt.

Synchronous belts have various advantages. Synchronous belts are generally more durable, as they have low installation tension and less stress on the drive system. However, when choosing a timing belt, it is important to consider the conditions that apply to your application. Ideally, you will choose a toothed belt with the lowest possible installation tension. Then, you’ll be on your way to a more efficient drive.

They transfer rotary motion from the central motor to the drive pulley

Timing belts are a common type of transmission, which transfers rotary motion from the central motor to the driving pulley through a series of pulleys. Their basic design is the same as an open belt drive, but they have an idler pulley in the middle to increase the tension and power transfer. Another type of drive is a stepped pulley, which allows different speeds and torques to be obtained.

The center distance between the pulley and the drive pulley determines their distance from each other. The distance between the pulley and the drive pulley determines how much power is transmitted through each pulley. When the pulleys are cross-connected, they cannot transmit as much power as they could if they were parallel, which limits the transmission of torque and prevents parts from breaking.

The main advantages of a timing belt are its comparatively low weight and low maintenance requirements. It has a tensile strength of about 90 percent and is also resistant to harsh conditions. The best timing belt pulleys are made of steel because they are resistant to wear and corrosion and can handle long-term chemical exposure. Plastic timing belt pulleys are also available. These are the lightest and cheapest options for the operator.

Another type of timing belt is a spring belt. Like elastic belts, spring belts are composed of a helical steel spring. They are typically used in model and toy engines for transmission from the crankshaft to other parts of the vehicle. Compared to elastic belts, spring belts last longer and do not have to be adjusted, although the spring belts are more likely to slip under heavy loads.

They are quieter

When choosing a replacement timing belt for your car, consider whether you prefer a rubber belt or a metal one. Rubber timing belts are more prone to wear out over time, while metal timing chains are durable and last longer than their rubber counterparts. Timing belts and chains both need maintenance to keep them operating smoothly and quiet. Listed below are some of the most common benefits of timing belts. Read on for more details.

While both timing belts and chains perform the same function, timing belts are quieter and more affordable. Although timing belts are cheaper to produce, they last less. In addition, timing chains are stronger and less likely to fail. If you’re considering changing your timing belt, you can find a good video about the pros and cons of each. Both belts and chains work to optimize fuel economy, reduce emissions, and improve engine efficiency.

Timing belts are much quieter than rubber belts. However, they are not as effective at regulating engine timing. If you’re concerned about noise when changing timing belts, make sure they’re properly fitted. If your timing belts are too loose, they can cause engine damage. A loose timing belt can force other parts out of sync, and can even cause a serious engine malfunction. Timing belts are quieter than rubber belts, but they’re no match for the sound-proofing properties of rubber.

While the noise of a timing belt can be bothersome, it’s a simple process that will help you drive your car more quietly. Their function is simple and straightforward: the timing belt keeps the engine running at the right speed, and they’re also cheaper than other mechanisms. They’re also easier to maintain and use at high speeds without any problems. Timing belts are available in many different tooth profiles, pitch lengths, widths, and materials. Some manufacturers even offer customized belts for specific purposes.

They are more efficient

Timing belts are more efficient than chains because they have a smaller cross-section and smaller bend radius. These characteristics also enable them to have a smaller overall cost. However, because they require more energy to operate, V-belts are typically chosen because of their relatively low face-value cost. This is because they are less expensive overall, but can cost more over time when you factor in their operational costs. Even so, the initial product cost can be paid off in the first month or 2 with energy savings.

Using a timing belt can greatly improve energy efficiency in many applications. Not only does it increase the torque and power transmitted, but it also minimizes friction and elongation losses. This can lead to a 15 percent energy savings, which is equivalent to EUR 2,390 per year in energy costs! The benefits of timing belts are also numerous. By eliminating the need for tooth-drive sprockets, timing belts can improve the efficiency of a drive system.

In many automobiles from the 1980s to the early 2000s, timing belts were a popular choice. This is because they were less expensive and durable, yet still capable of maintaining the correct timing of an engine. However, timing chains are more reliable these days, and many drivers opt for them over timing belts. They are quieter and last longer, which makes them more desirable for drivers. In general, timing chains are cheaper but less efficient than belts.

Timing chains were a more expensive option, but the oil crisis pushed manufacturers to make cars with fuel efficiency their top priority. With timing belts, manufacturers realised that they were cheaper, easier to install, and more reliable. However, timing chains had a few drawbacks. One of the main disadvantages was that they were harder to replace, and required more engine oil. But with the price of fuel and gas, timing chains were preferred by many drivers.

They require lubrication

Timing belts are an integral part of engine performance. They keep the engine’s valves open and closed at the correct times and are designed to fit around the gears inside the engine. Timing belts do not require lubrication but are still important to keep the engine working smoothly. Self-servicing car parts can be used to maintain the health of your timing belt. Here are some helpful tips for self-servicing your timing belt.

When timing belts are wearing out, they can cause a noise. This noise is usually due to impact, where the belt tooth engages with the pulley. While the noise isn’t particularly annoying, it can be damaging over time. The second noise that you may hear is called air volume displacement. It occurs when air fills the space between the belt and the pulley and increases with the speed of the engine.

In addition to timing belts, timing gears and chains are often inaccessible, with their hidden mechanisms. The year and type of engine will determine which type you have, but each type is susceptible to wear and tear. Timing gears and timing belts are usually coated in engine oil for protection. Lubricating them regularly will ensure that they work as they are supposed to. These belts can also be driven by other components in the engine, which will require lubrication.

Oil leaks can lead to timing belt failure. If you notice a leak in the oil, try to identify it as soon as possible. Getting your timing belt replaced will prevent downtime caused by engine failure. You may also notice clunks, grinding noises, and knocking sounds under the vehicle. These are common signs that your timing belt needs lubrication. You can reduce the chances of these problems by regularly changing the engine oil and making sure it is of high quality.

China best New V Belt Tensioner V Belt Wholesale Engine Rubber Fan V Belt near me manufacturer

Product Description

Product Description:

The top and the bottom are encased by the weapper, Both sides are rubber . V belt of tooth shape groove is designed for the bottom to improve the tlexral property.

| No. | Name | Function | Material |

| 1 | Top Fabric | Protect the CZPT tensile member | Polyester Cotton Canvas |

| 2 | Core Cord | Nuclear material to pass the dynamicTop Fabric force | Polyester |

| 3 | Bottom Rubber | Side compression resistant and section | CR,EPDM |

| 4 | Bottom Fabric | Absorb the impact and prevent crack of the core rubber | Elastic Fabric |

| Section Size of lndustrial Raw Edge V Belts |

| Type | Top width (mm) | Belt Thickness (mm) | Angle(°) |

| HM | 10.5 | 8.0 | 38 |

| AX | 13 | 8.0 | 38 |

| BX | 17 | 11 | 38 |

| CX | 22 | 14 | 38 |

| DX | 32 | 19 | 38 |

| EX | 38 | 23 | 38 |

| Section Size of Raw Edge Narrow Belts |

| Type | Top width | Belt Thickness | Angle |

| XPZ | 9.7 | 8.0 | 40 |

| XPA | 12.7 | 10 | 40 |

| XPB | 16.3 | 13 | 40 |

| XPC | 22 | 18 | 40 |

| 9NX | 9.5 | 8 | 40 |

| 15NX | 16 | 13.5 | 40 |

| 25NX | 25.4 | 23 | 40 |

| Section Size of Raw Edge V Belts for Automobile |

| Type | Top width | Wrapped V belt | Raw edge V belt | REF | REC | Angle |

| AV-10/9.5 | 10.0 | 8.0 | 7.5 | 7.5 | 8.0 | 40 |

| AV-13/12.5 | 13.0 | 10.0 | 8.5 | 8.5 | 9.0 | 40 |

| AV-15 | 15.0 | 9.0 | – | – | – | 40 |

| AV-17 | 16.5 | 10.5 | 9.5 | 9.5 | 11.0 | 40 |

| AV-22 | 22.0 | 14.0 | – | – | 13.0 | 40 |

Company introduction:

The First:HangZhou Grand AUTO PARTS CO.,LTD.is a professional auto parts corporation with operations including development,productnumber of high-tech production bases in mainland China.

The Second:We have established partnerships with big purchasers and the renowned brands in France and Egypt and Iraq to carry out the OEM.

The Third:The products are sold into over 50 countries around the world with Europe, America,the middle east and the southeastAsia and Africa as the main destinations.

Replacing a Failing Drive Belt Tensioner

A failing drive belt tensioner can be extremely costly. Here’s what to look for and what to do if you suspect yours is bad. In addition, you’ll learn how to identify Idler pulleys and repair it yourself. If the tensioner is failing, you should replace the belt, as well as the Idler pulleys and shaft bearings. But what if the tensioner isn’t faulty?

Symptoms of a bad or failing drive belt tensioner

If your car’s drive belt is not moving smoothly, the pulley may be at fault. Ideally, the tensioner pulley should move away from the engine when the car starts. However, if it stays put or starts to move toward the engine, it’s time to replace the tensioner. The belt may also start to exhibit different wear patterns, such as the uneven wear of the sprockets, bearings, and springs.

If the serpentine belt begins to look loose and the engine loses its luster, the problem is most likely the bad drive belt tensioner. This issue will result in engine vibration. A faulty drive belt tensioner may also lead to a faulty spark plug, which prevents fuel from burning in the combustion chamber. This issue will likely require an engine diagnostic tool, such as an OBD2 scanner, to determine the cause of the check engine light.

Another sign that your drive belt tensioner is failing is a chirping noise. This noise can occur intermittently or constantly, and it may signal a problem with the pulley. In some cases, a faulty pulley may even cause your engine to misfire. Additionally, you may notice that the engine won’t start, even if you engage the starter motor.

In addition to the noise that may come from a failing tensioner, the bad belt tensioner may cause your serpentine to fail. In addition to the noise, this can also lead to overheating of the engine, which can result in costly damages. In addition to causing engine damage, a bad belt tensioner won’t reserve the minimum tension it needs to do its job and may even exceed it, causing the belt to wear out much faster.

If you notice any of these symptoms, it may be time to replace the drive belt tensioner. You can find a replacement OEM part online at a discounted price, as they’re available in wholesale quantities. A Mazda engine typically has no other parts blocking the serpentine belt path, so you can easily find the part you need. After replacing the drive belt tensioner, you’ll need to replace the serpentine belt as well.

Cost to replace a drive belt tensioner

Depending on the location and type of vehicle, replacing a drive belt tensioner can cost between $235 and $267. Some repairs may require other parts, such as a serpentine belt or tensioner housing. RepairPal’s Fair Price Estimator can help you get an accurate estimate for your particular vehicle. You can also contact HomeX, a virtual repair shop that can fix simple issues like loose drive belt tension.

It’s a relatively simple DIY job for most cars. An experienced mechanic will be able to replace the belt in a half hour or less, depending on the type of car and how many parts are affected. Depending on the complexity of the repair, the labor to replace the drive belt tensioner could cost anywhere from $50 to $170. The labor to replace the drive belt tensioner is typically included in the quoted price, but some auto shops may charge more to replace other car parts as well.

Replacing the drive belt tensioner is a relatively easy task. While the process might take an hour or more, it will be worthwhile in the long run. Regular inspections can prevent costly repairs by identifying problems before they cause major damage. A car’s belt is essential to the operation of the engine and can’t be operated without it. Changing it can save you money, as it will save you from spending extra on unnecessary parts.

Thankfully, there are plenty of tools available to help you replace your drive belt. While it may not be the easiest repair, it will still cost less than a mechanic’s service call. It is better to replace the belt early than to wait for the vehicle to break down, as this will prevent more expensive parts from breaking. You may also consider investing in a premium belt, which will give you twice as much mileage as a cheaper one.

While a drive belt tensioner is generally considered a wear-and-tear item, it is a part that should last the entire life of the vehicle. You can expect to replace the drive belt tensioner no earlier than 125,000 miles, but it is better to do it early if your car isn’t that old. And it doesn’t hurt to check the owner’s manual for directions on how to replace the drive belt tensioner.

Idler pulleys

Idler pulleys may seem like a minor part of your car, but their important job is to keep various components in good working order. Fortunately, they are inexpensive and don’t need much maintenance. If 1 pulley fails, it is best to replace all of them. However, it is not always easy to check idler pulleys yourself. It’s recommended that you visit a professional auto repair shop that is ASE-certified to inspect and replace the idler pulley.

Depending on the size and type of idler pulleys you need, you’ll have to purchase 2 or 3 pieces. You’ll need to purchase a pair of pliers for this part, as well as a tensioner pulley wrench. The cost of a replacement idler pulley will vary by make and model, but you can expect to pay between $40 and $200. These prices don’t include taxes or fees. Because they are so essential to drive belts, it’s worth investing in 1 or two.

Idler pulleys are a vital part of a car’s engine. They’re found underneath the hood and are usually 2 to 4 inches in diameter. They run over a roller that’s used to tension the belt. The belt is wrapped around a series of engine parts, and the idler pulleys are a complement to each other. You may not need an idler pulley on your car, but your mechanic will install it for you if you don’t.

The idler pulleys for a belt tensioner are crucial parts of your car’s engine. If they are worn down, the belt is likely to move loosely over them. Corrosion may also make the idler pulley move less freely. If the idler pulley is slipping, the belt may jump over the pulley, and the squealing noises will indicate a serious problem.

The idler pulley is a pivotal part of the engine’s power train. It redirects the path of the serpentine and timing belts, so that they can make optimal contact. The larger the contact patch, the more power the belt will transfer. The idler pulley can also improve the vehicle’s performance. It is a vital part of the engine, so make sure you check it frequently and install it correctly.

Repairing a drive belt tensioner

Replacing a drive belt tensioner is relatively simple. While your belt may need to be replaced, other parts of your engine may also need to be fixed. Typically, the tensioner will be replaced along with the pulley, as both parts are prone to malfunction. Replacing the drive belt tensioner is a fairly straightforward job, and it should only take about an hour or two. By following these simple steps, you can save yourself a lot of money and time.

You can detect the problem by observing the belt glazing. Typically, it occurs when the tensioner does not have enough spring tension. Another sign of a failed component bearing is excessive arm oscillation. Excessive chattering and oscillation indicate that the damper has worn out. If you notice excessive oscillation, you should replace the tensioner pulley. Otherwise, you might be dealing with a defective bearing.

A damaged or out-of-adjusted drive belt will make a squealing noise. This is due to the belt slipping on the pulleys. It is most noticeable when the car is first started in the morning. A damaged drive belt will also be hard to manipulate. The new belt should be the same length and width as the old one. You can check the tensioner by pulling the belt and compressing it.

A worn-out drive belt tensioner will result in unusual noise, excessive wear, and a loose belt. This is especially affecting if the car is equipped with a serpentine belt. The drive belt tensioner has a roller bearing that can wear out, which will cause a squealing noise or even cause the belt to roll off entirely. Because of its important role in engine operation, it is vital to check the condition of the drive belt tensioner on a regular basis.

While replacing a drive belt tensioner may seem like a simple DIY project, you should consult a mechanic before undertaking the work. The parts and labor costs of a drive belt tensioner repair can range from $140 to $400, and you should allow an hour for this repair. If you are not comfortable performing the repair yourself, you can always hire a mechanic to do it for you. In most cases, a drive belt tensioner replacement will cost approximately $70 to $80 and take about an hour.

China factory CZPT Isle 6L Qsl9 Truck Engine V Belt Tensioner 3974102 for Truck and Excavator with Best Sales

Product Description

Xihu (West Lake) Dis.feng ISLE 6L QSL9 truck engine v belt tensioner 3974102 For Truck and excavator

Our Main products : cylinder block,cylinder head,crankshaft,camshaft,connecting rod,connecting rod bearing,valve,plunger,nozzle,exhaust valve,engine assy,feed pump,fan blade,gasket kit,glow plug/engine preheater,intake valve,liner,liner kit/rebuild kit,main bearing/crankshaft bearing,nozzle,nozzle piping,oil pump,piston,piston pin,piston ring,plunger,seat ,thrust bearing,valve guide,valve seat,valve seal,gasket full set ,water pump , turbocharger,genarator, starter,sensor…

| USE FOR | EXCAVATOR/ Truck |

| MACHINE MODEL | QSL9 |

| PART NUMBER | 3974102 |

| BRAND | Cummins |

Why choose our company?

——Company information

HangZhou Marun Machinery Equipment Co., Ltd is located in HangZhou China,Our company

established in 2008, it’s parent company -HangZhou Qipeng Machinery Equipment Co,.Ltd. We are authorized agent of Isuz,Yanmar and Mahle in China, agent of Isuz since it founded in 1990 ,specialized in excavator engine spare parts ,engine assembly and construction machinery for 30 years.

About ISUZ :

As a largest, most varieties and professional,leading ISUZ agent in China, we offer a full range of genuine ISUZ engine accessories and complete engine.The business scope are as follows:

Engine model:4JB1,C240,4BD1,4LE1,4LE2,4JG1,4JG2,4BD1,4BG1,4HK1,6HK1,6BD1,6BG1,6SD1,6RB1,6UZ1,6WG1.

Besides , we also can supply parts for machines like SUMITOMO,CASE,KOBELCO ,MITSUBISHI,CUMMINS ,KAWASAKI and so on

About CZPT :

As we all knows,if there were only two cars in the world, then one must use MAHLE spare parts.It’s products range cover construction machinery engine parts and auto engine parts,parts including:piston/cylinder/liner kit/valves/bearings/gasket kit/piston ring/filter .Apply to ISUZ,KOBELCO,CATER,KOMATS,CUMMINS,MITSUBISHI,HINO,DEUTZ and so on .

——Company Advantages

1. We have profession knowledge about engine parts ,more than 20 years experience in engine parts.

2. We can offer new and used genuine parts, oem, good quality made in china parts to you.

3. The genuine parts will give weight,price when quotation.

4. Genuine stock pictures will send if you need .

5.All parts can check with part number,all parts can order follow part number.

6. Quick delivery time,will delivery the goods within 3 days.

7. Safe packing to protect the goods, such as wooden box, Iron sheet for our parts.

8. Small quantity can accept.

——FAQ:

Q1:How long is the warranted time?

For natural broken, 3 months. Guarantee genuine parts.

Q2: What’s payment you can accept?

T/T, WESTERN UNION, CHINESE BANK,

Q3: What’s package? Can you give me the package according my requirement?

Yes, Original packing or Neutral packing with wooden box or carton

Q4: How about the lead time?

1) Stock available: 1-3days.

2) Out of stock: It’s according to your quantity, and we have cooperated with factory.

We will let you know when we quote.

Q5: What’s the shipping way you can offer?

1) Big order: By sea or by air.(It can reduce the costs)

2) Small order: DHL, TNT, UPS, FEDEX, EMS,

Q6: Whta’s the terms of the transaction?

EXW, FCA, FAS, FOB, C&F, CIF, CPT, CIP, DAF, DES,DDP.

Q7: Do you accept small order?

Yes, small order can accept.

Q8: What’s brand you can offer in your company?

1) OEM, 100% GENUINE PARTS, COPY(Made in China)

2) GENUINE PARTS.

We are seeking the chances to meet all the friends both from at home and abroad for the CZPT cooperation.

We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

,

Why Timing Belts Are So Important